4.4 Investigating the B-Rich Phase in NdFeB Magnetic Alloys: Structure and Magnetic Properties

People have made many studies since the birth of high - performance NdFeB magnetic alloys. This permanent magnetic alloy has the \(Nd_{2}Fe_{14}B\) compound as the base phase and contains Nd - rich phase, B - rich phase and sometimes a small amount of \(\alpha - Fe\). The studies on \(Nd_{2}Fe_{14}B\) and \(RE_{2}Fe_{14}B\) compounds have been relatively in - depth. The relationship between B - rich phase and magnetic hardening is attracting people’s attention. D. Givord, et al elaborated the B - rich crystal structure under a long periods and ultra - structure model of \(Nd_{5}Fe_{18}B_{18}\) (Givord, Moreau, Tenaud, 1985). Regarding the sensitivity of the coercivity with microstructure, the author observed the microstructure of NdFeB alloy, especially the variety of the microstructure of B - rich phase with change of temperature, and discussed the coercivity mechanism of NdFeB permanent magnetic alloy by combining other results.

Preparation Process and Experimental Methods for Studying the B-Rich Phase in NdFeB Alloys

The alloy was melted in a non - consumable vacuum arc furnace with the constituents of high purity material of metallic neodymium, boron powder, and metallic iron. And the ingot was pulverized into powder of 3μm under protection of argon atmosphere and was formed under 1.5 T magnetic fields. Then it was sintered at 1100°C and proceeded aging at 600°C. The above sample was sliced into lamellas of 0.25 mm in a direction vertical to \(c\) axis and then was thinned mechanically to 0.025 mm. Afterwards the observable filmy specimen was obtained by ion thinning. The observation was carried out in a JEM - 1000 kV HVEM equipped with a heating apparatus. The specimen for X - ray diffraction analysis and Mössbauer experiment was all in fine powder with a size passing through 325 mesh sieve (0.043 mm).

In-Situ and Dynamic TEM Observation of \(Nd_{1.11}Fe_4B_4\): Microstructural Insights

Pattern at room temperature

Appearance of B - rich phase at room temperature is shown in micrograph of Fig. 4.18.

It can be seen from the micrograph that the B - rich phase locates in the triangle crystal boundary of the base phase, where the Nd - rich phase also exists. Some part of the B - rich phase directly contacts with the base phase, and in some areas, there is a mingled transition area of the B - rich phase and Nd - rich phase. High - density defects exist in the interior of the B - rich phase, which are represented as striae, alternating with bright and dark regions, paralleled in direction vertical to \(c\) axis.

The electronic diffraction pattern of B - rich phase at room temperature is shown in the top right part in the micrograph of Fig. 4.18. The tetragonal system was demarcated, and as the result the Fe - B substructure was obtained with crystal lattice parameters as: \(a = 0.712\ nm\), \(c_{Fe - B}=0.389\ nm\). This result basically accords with that by X - ray diffraction (Givord, Moreau, Tenaud, 1985). Meanwhile a phenomenon can be observed that reciprocal pole was elongated.

Microstructure at high temperature

The \(Nd_{15}Fe_{78}B_{7}\) specimen was heated in the HVEM and the whole process was videotaped. And the observation was carried out for variation of microstructure of the permanent magnetic alloy. It was found that there almost had no change at 25 - 100°C (Fig. 4.19). But at 140°C the defect was observed in interior of B - rich phase, and especially at 280°C that the precipitates appeared in B - rich phase. The further analysis was not carried out for the precipitates because the precipitate particles were too small. Electronic diffraction indicated that the microstructure also vitiated remarkably at 322°C, but its appearance recovered again to be similar to that at room temperature at 500°C, as shown in the micrograph of Fig. 4.20.

X-Ray Diffraction and Mössbauer Spectroscopy Analysis of \(Nd_{1 + \varepsilon}Fe_4B_4\)

In order to study the structure and specialty of B - rich phase of \(Nd_{1+\varepsilon}Fe_{4}B_{4}\), the alloy was confected as per composition of \(Nd_{1.1}Fe_{4}B_{4}\) and annealed at 1,100°C for 25 days. It was discovered by X - ray diffraction that the powder diffraction pattern was composed of 2 sets of lines. It was revealed by strength computing that the relatively sharp line came from the contribution of Fe - B substructure; and that the relatively dispersed one was correspondingly the neodymium substructure. The result can be obtained by self - editing computer indexing program that: \(a = 0.7116\ nm\), \(c_{Fe - B}=0.3894\ nm\), \(c_{Nd}=0.3523\ nm\).

Mössbauer spectrum of \(Nd_{1.1}Fe_{4}B_{4}\) is fitted by Lorentz line type using the least square method, the detailed result analysis can refer to reference (Pan, Ma, Ping, et al, 1991). The Mössbauer spectrum of \(Nd_{1+\varepsilon}Fe_{4}B_{4}\) compound is two fourth - grade split peaks, as shown in Fig. 4.21. This indicated that the \(Nd_{1+\varepsilon}Fe_{4}B_{4}\), i.e., the B - rich phase, appeared as paramagnetic. Ultra - subtle parameter is \(I. S.=0.03\ mm/s\) and the fourth - grade split is \(Q. S.=0.56\ mm/s\). Split of ferromagnet still was not found from the Mössbauer spectrum measured at temperature of liquid nitrogen. That indicated that the atomic order temperature for ferromagnet is at least below 77 K. And the result of relevant magnetic measurement shows that the Curie temperature is about 14 K for B - rich phase (Givord, Moreau, Tenaud, 1985; Pan, Ma, Ping, et al, 1991; Bezinge, Braun, Muller, et al, 1985).

Structural and Magnetic Analysis of the\(Nd_{1.1}Fe_4B_4\) phase

Based on elaborated crystalline structure, D. Givord, et al indicated that chemical

The formula of the B - rich phase could be formulated as \(Nd_{1+\varepsilon}Fe_{4}B_{4}\), where \(\varepsilon = c_{Fe - B}/c_{Nd}-1\), which can be derived from data of X - ray diffraction. It is noticed that there is not a simply multiple relation between \(c_{Fe - B}\) and \(c_{Nd}\), thus this compound may belong to an one dimension composition varying type inhomogeneous structure. The \(Nd_{1+\varepsilon}Fe_{4}B_{4}\) compound may also be described as “infinitely adaptive structure”(Anderson, 1973). The phenomenon that double periods subsisting in the same crystal structure had been discovered in \(MnSi_{2 - x}\) and the interrelated Nowotny phase (Zwillling, Nowotny, 1971). In order to project the specialty of double periods that is normally called as veneer structure or chimney - ladder structure.

It can be observed from X - ray diffraction pattern that the lines in sublattice of neodymium appeared widening obviously. This apparently may not be attributed to interior stress or over fined crystal particle because there were only a few lines being widened but not all diffraction lines of \(Nd_{1+\varepsilon}Fe_{4}B_{4}\) compound being widened. We consider that this may be a result of interaction of inter - sublattice. Modulation of Fe - B sublattice to neodymium sublattice made one direction of neodymium sublattice lose periodicity, which resulted in unequal space among crystalline planes and resulted in widened lines. In fact the Fe - B sublattice is also modulated by neodymium sublattice. A. Bezinge, etc. observed the kink modulation of Fe - B sublattice (Bezinge, Braun, Muller, et al, 1985). That may be related to interaction of sublattice structures.

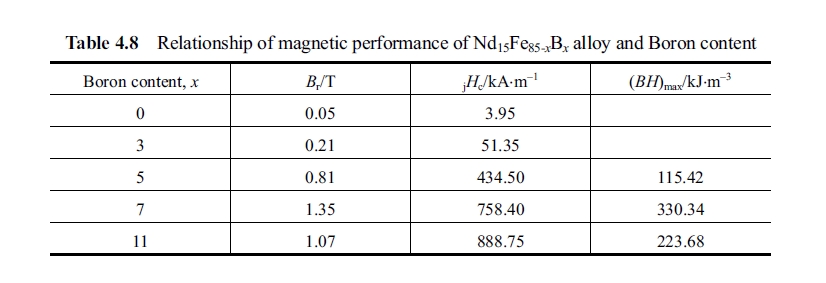

At the same time we observed that the interior crystals of \(Nd_{2}Fe_{14}B\) base phase appears relatively high integrity, where have no defect, nor precipitate. Therefore, no matter nucleation center of reverse domain or pinning point all unable to exist in crystals of \(Nd_{2}Fe_{14}B\). The magnetic hardening related to microstructure in crystalline boundary. The B - rich phase is paramagnetic at room temperature so that it can act as function of inclusion pinning on domain wall and heighten the coercivity. Table 4.8 indicates relationship between magnetic property and boron content in the alloy. It can be seen from the table that the property reaches optimum when the boron content is 7% (at.). The superfluous boron would cause decline in value of \(B_{r}\) and \((BH)_{max}\), but the coercivity is heightened. Apparently, when boron content exceeding 7% (at.) and reaching 11% (at.) the saturated magnetization strength will decline and so that depress the remanence because iron and neodymium are reduced comparatively in proportion of the alloy. After formation of sufficient \(Nd_{2}Fe_{14}B\) and B - rich phase in the remanent will mainly B - rich phase. The quantitative analysis on the phase proceeded in our early work indicated that boron content in the B - rich phase of the alloy will increase from 4.6% to 10.4%, more than doubled, when boron content is increased from 7% (at.) to 11% (at.). Thus the coercivity is heightened 130.35kA/m accordingly. We deemed that increase of B - rich phase enhanced the pinning ability of crystalline boundary for anti - magnetization process and so that resulted in enhancement of coercivity. This is because energy of domain wall (\(\gamma\)) is proportional to volume \(V\) of additive phase. Therefore, it can be explained by formula 4.3 for enhancement of \(H_{c}\) by increasing B - rich phase:

\(H_{c}\propto\frac{1}{2M_{s}}\left(\frac{\partial\gamma}{\partial x}\right)_{\text{max}}\) (4.3)

Understanding the Relationship Between the B-Rich Phase and Coercivity in \(Nd_{1.1}Fe_4B_4\) Magnetsy

The high - density defects in B - rich phase can be observed obviously, and the phenomenon of elongated reciprocal pole in electronic diffraction spectrum may be related to these defects in B - rich phase. Existence of high - density defects can enhance pinning ability on domain wall so that further heightens the coercivity. It can also be seen the Nd - rich phase and filmy belt besides the B - rich phase in NdFeB. Thus mechanism of coercive force is a complicated problem and the relative studies are under way (Pan, Zhao, Ma, 1988; Pan, Ping, Liu, et al, 2003; Pan, Liu, Luo, 1990; Pan, Ma, Li, 1993).

K. J. Strnat, et al (Strnat, Li, 1985) discovered that the coercivity of NdFeB permanent magnetic alloy almost disappeared at 265°C. This change is very possibly related to variation of microstructure with change of temperature, besides the contribution by heat activation. For different pinning instance the dependency relationship of coercivity on temperature is different. Our observation indicated that the B - rich phase normally locates at trigonal crystalline boundary and distributes very dispersed. The pinning points are of low density thus they may become weak pinning, then the relation between \(H_{c}\) and temperature may be represented as:

\((H_{c}/H_{o})^{1/2}=1 - \left(\frac{75KT}{Abr}\right)^{2/3}\) (4.4)

This formula is consistent with experimental data by Handjipanayis, et al (Handjipanayis, hawless, Dickerson, 1985).

Conclusions: Key Findings on the Role of the B-Rich Phase in \(NdFeB\) Alloys

- The chemical formula for B - rich phase is \(Nd_{1+\varepsilon}Fe_{4}B_{4}\), it possesses a very special crystal structure because there is not a simply multiple relation between \(c_{Fe - B}\) and \(c_{Nd}\). Thus the B - rich phase may be an one dimension component variation type commensurate structure and this compound is similar to Nowotny phase of \(MnSi_{2 - x}\) etc., or a chimney - ladder structure.

- The B - rich phase becomes paramagnetic phase at room temperature. They locate in a triangular crystal boundary and can become pinning point on the domain wall of anti - magnetization nucleus that avails enhancement of coercivity.

- There are high - density defects existent in B - rich phase. These defects are perpendicular to \(c\) axis, and that may enhance pinning ability of B - rich phase on domain wall.

- The coercivity is related to microstructure but the microstructure varies with change of temperature. Therefore, the further observation of relationship between microstructure and temperature will be helpful for understanding of coercivity mechanism.