2.6 Analysis of the Magnetic Hysteresis Loop in SmCo₅ Permanent Magnetic Alloy

Observation on SmCo₅ Permanent Magnet hysteresis loop of material and study the reason for using various shape of the loop is a way to analyze difference of material and seek a approach to improve performance of materials. However, to obtain an exact magnetic hysteresis loop normally need a magnetic measurement apparatus with mag-netic field intensity over 100,000 Gs. This apparatus was lacked and some had bad exactness before in continent of China. Therefore, we used the newly devel-oped strong magnetic field apparatus with magnetic field intensity near 200,000 Gs in physics institute to measure the magnetic hysteresis loop and the curve of the loop varying with temperature for three types of specimens (Yang, Zhao, Li, et al, 1983). This section emphasizes to introduce the measurement result and dis-cuss the result with combination of technical condition and observation result by electronic microscope.

Specimen Preparation, Magnetic Measurement, and Transmission Microscopy: Experimental Methodsd

All specimens used in experiment were prepared using alloy melting method (Pan, Jin, 1990); the alloy composition was prepared per atomic proportion of 1:5 for samarium and cobalt metals; melting was carried out using arc furnace. The melted liquid alloy with a composition of Sm 60%, Co 40% was used. The adding amount was 11% of total amount of the alloy. The melted alloy was crushed coarsely and then pulverized to around 5μm. The powder was oriented under a strong magnetic field and molded. After sintering the specimen was ready for measurement.

Instrument used for measurement was a strong magnetic field apparatus in Institute of Physics Chinese Academy of Sciences with a pulse magnetic intensity up to 200,000 Gs. The magnetic field wave was close to a half sine wave and its durative time was 15.9ms and was switch-controlled. The magnetic field could be reversed to adapt the measurement of the magnetic hysteresis loop. Magnetic field H and magnetization intensity 4πM was measured using induction method. Measurement scope was 77 - 550K.

Experiment used JEM-1000KV HVEM for dynamic observation on and heating specimen. Preparation method of specimen was sliced the alloy sample into 0.3 mm lamellae using a linear cutter; and then thinned the sample to about 100nm using ion; its accelerate voltage was 100kV and its current was 10μA.

Chemical Composition Analysis of Three Different SmCo₅ Specimens

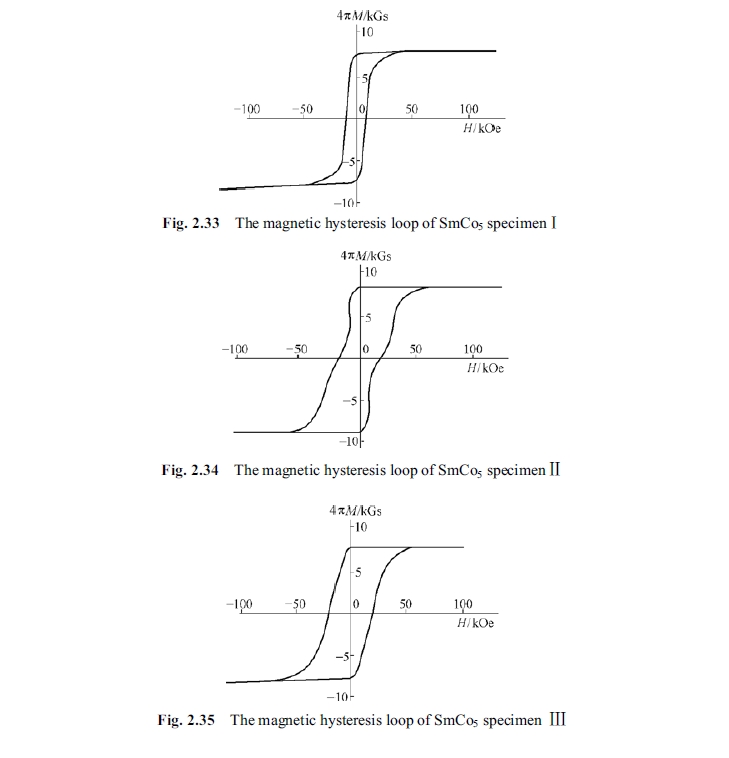

Fig. 2.33 to Fig. 2.35 show the magnetic hysteresis loops being measured of three types of different specimens (classified as three types, i.e., Ⅰ, Ⅱ and Ⅲ).

It can be seen from comparison between Fig. 2.33 and Fig. 2.34 that the magnetic hysteresis loop of the type Ⅱ (No.2) had a wasp waist shape and a bad quadrate degree. It can be seen compared with Table 2.6 that oxygen content of the specimen No. 2 was the highest.

Evaluation of Preparation Techniques for SmCo₅ Permanent Magnet

In preparation technique the type Ⅲ (No.3) specimen had a higher oriented field thus its quadrate degree of the loop was better than that of the type Ⅱ.

Magnetic Performance Curve and Analysis of SmCo₅ at 77-550K

The magnetic hysteresis loop was measured using 200,000 Gs magnetic field measurement apparatus at different temperature from 77K to 550K. The measurement obtained a variation curve of 1$H_c$ vs $T$ and $4\pi M_r$ vs $T$, as shown in Fig. 2.36 and Fig. 2.37.

It can be seen from Fig. 2.36 and Fig. 2.37 that \(4\pi M_r\) did not vary considerably along with rising of temperature. The coercivity variation speed of specimen type Ⅱ (No.2) was bigger than that of type Ⅰ (No.1) and type Ⅲ (No.3).

Transmission Electron Microscopy (TEM) Observation and Analysis of SmCo₅ Specimens

Observation using HVEM was carried out on microtexture of three types of specimens. Fig. 2.38 shows texture, dislocation network and precipitate particles of the specimen with a worst quadrate degree of magnetic hysteresis loop at room temperature. Fig. 2.39 is the microtexture, precipitate phase and dislocations of the specimen of type Ⅲ (No.3) with a better quadrate degree of magnetic hysteresis loop at room temperature. It is known from the observation by the microscope

that the specimen of type Ⅱ (No.2) had more precipitate phase than that in the specimen of type Ⅲ (No.3), i.e., had more precipitate which are not 1:5 phase (the specimen of type Ⅲ (No.3) was the 1:5 phase being testified through electronic diffraction analysis) (Pan, Jin, 1990; Pan, Zhao, 1989).

Conclusions: Key Insights from the Magnetic Hysteresis Loop Study of SmCo₅s

Through measurement of magnetic hysteresis loop and magnetic parameters, and observation using 1000 kV HVEM it is concluded: to obtain material with good quadrate degree of magnetic hysteresis loop and high magnetic performance it is necessary to decrease oxygen content, increase magnetic field intensity in powder molding and strictly control sintering process to avoid precipitation of non 1:5 phase besides paying attention to components of raw material.