Samarium Cobalt Magnet

- Home

- Samarium Cobalt Magnet

What are Samarium Cobalt Magnets (SmCo Magnets) ?

SmCo magnets are divided into two main series: SmCo_5 (1:5 series) and Sm_2Co_17 (2:17 series), which refer to the ratio of samarium to cobalt in the alloy. These magnets offer unique advantages in various applications, particularly where performance at high temperatures is critical.

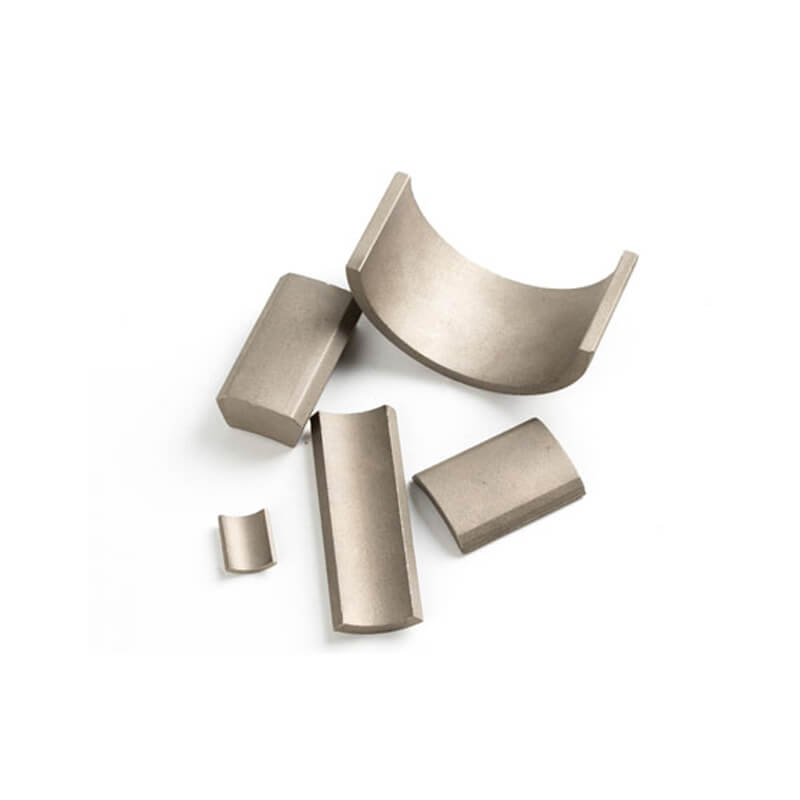

Samarium Cobalt Magnets

Samarium Cobalt Magnets Advantages

- High resistance to temperature changes (up to 300°C).

- Superior corrosion and oxidation resistance.

- Excellent magnetic strength retention in extreme high or low temperatures.

Our Related Product

How are samarium cobalt magnets made?

Samarium cobalt machining

As briefly mentioned above, SmCo is as brittle as the neodymium rare-earth magnet. It could cut and crack easily. Hence, users are not advised to use crude tools to machine samarium cobalt magnets. Special diamond tools should be used for grinding instead. Likewise, grinding work must be done with generous amounts of coolant to reduce the damage that could arise due to heat, such as fires (for flammable dust caused by grinding) or cracks. It's wise to let professional machinists do the grinding work.

Handling tips

Although a samarium cobalt magnet boasts a very strong magnetic field, it may crack or chip easily. The same case applies to neodymium rare-earth magnets. They are brittle and must all be handled with a lot of care. Proper handling can prevent personal injuries and hazards. These magnets should never be allowed to accelerate at a high speed to an attracting object. They could collide and shatter into particles. Kids should not handle SmCo magnets or any other rare-earth magnets as these can be very dangerous if swallowed or allowed to pinch the skin.

Samarium cobalt machining

As briefly mentioned above, SmCo is as brittle as the neodymium rare-earth magnet. It could cut and crack easily. Hence, users are not advised to use crude tools to machine samarium cobalt magnets. Special diamond tools should be used for grinding instead. Likewise, grinding work must be done with generous amounts of coolant to reduce the damage that could arise due to heat, such as fires (for flammable dust caused by grinding) or cracks. It's wise to let professional machinists do the grinding work.

Handling tips

Although a samarium cobalt magnet boasts a very strong magnetic field, it may crack or chip easily. The same case applies to neodymium rare-earth magnets. They are brittle and must all be handled with a lot of care. Proper handling can prevent personal injuries and hazards. These magnets should never be allowed to accelerate at a high speed to an attracting object. They could collide and shatter into particles. Kids should not handle SmCo magnets or any other rare-earth magnets as these can be very dangerous if swallowed or allowed to pinch the skin.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the samarium cobalt magnet. If you want to know more about samarium cobalt magnets or other magnet products, we advise you to visit Stanford Magnets for more information. As one of the leading suppliers of magnet products across the world, Stanford Magnets has rich experience in the manufacture and sale of various magnets. We provide our customers with high-quality rare earth permanent magnetic products such as neodymium magnets, and other non-rare earth permanent magnets at a very competitive price.

About Of A Author : John Smith

John Smith is an expert at Stanford Magnets, where she shares her deep knowledge of magnets like Neodymium and Samarium Cobalt. With a background in materials science, Cathy writes articles and guides that make complex topics easier to understand. She helps people learn about magnets and their uses in different industries, making her a key part of the company's success.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the samarium cobalt magnet. If you want to know more about samarium cobalt magnets or other magnet products, we advise you to visit Stanford Magnets for more information. As one of the leading suppliers of magnet products across the world, Stanford Magnets has rich experience in the manufacture and sale of various magnets. We provide our customers with high-quality rare earth permanent magnetic products such as neodymium magnets, and other non-rare earth permanent magnets at a very competitive price.

About Of A Author : John Smith

John Smith is an expert at Stanford Magnets, where she shares her deep knowledge of magnets like Neodymium and Samarium Cobalt. With a background in materials science, Cathy writes articles and guides that make complex topics easier to understand. She helps people learn about magnets and their uses in different industries, making her a key part of the company's success.

Information of our Samarium Cobalt Magnets (SmCo Magnets)

How do SmCo magnets compare to Neodymium (NdFeB) magnets?

While both SmCo and NdFeB magnets are considered rare-earth magnets and possess high magnetic strengths, SmCo magnets excel in high-temperature environments and have superior corrosion resistance without the need for protective coatings. Neodymium magnets are generally stronger at room temperature and are more cost-effective but have lower temperature resistance and are more prone to corrosion.

What are Samarium Cobalt (SmCo) magnets?

Can SmCo magnets work under high temperature?

What are the main applications of SmCo magnets?

How strong are SmCo magnets?

Are SmCo magnets corrosion-resistant?

How are SmCo magnets made?

Are there any handling concerns with SmCo magnets?

Samarium Cobalt (SmCo) Disc Magnets

Samarium Disc magnets FAQs.

What are SmCo disc magnets?

Can SmCo disc magnets operate at high temperatures?

What applications are SmCo disc magnets used in?

How strong are SmCo disc magnets?

Do SmCo disc magnets need protective coatings?

Are SmCo disc magnets brittle?

How are SmCo disc magnets manufactured?

Neodymium Magnets Manufacturing Process

Samarium Cobalt Rod Magnets

What are SmCo rod magnets?

What are the main applications for Smco rod magnets?

Can SmCo rod magnets operate in high-temperature environments?

making them suitable for high-temperature applications.

Do Smco rod magnets require any handling?

Are SmCo rod magnets corrosion-resistant?

How are SmCo rod magnets manufactured?

What sizes and grades are available for SmCo rod magnets?

Samarium Cobalt Pot Magnet

A Samarium Cobalt (SmCo) pot magnet is a type of assembly that combines a SmCo magnet encased in a steel shell or pot. This configuration enhances the magnetic force on one side of the magnet by directing the magnetic field to a specific area, thereby increasing the holding or attracting power while protecting the magnet from damage or corrosion. SmCo pot magnets are especially valued for their high temperature resistance and corrosion resistance, making them suitable for use in environments where these properties are critical.

What is a Smco pot magnet?

A SmCo pot magnet is a type of magnetic assembly that consists of a Samarium Cobalt (SmCo) magnet encased in a metal “pot” or shell. This design concentrates the magnetic field on one side of the assembly, enhancing the magnet’s holding power while protecting the magnet from physical damage and corrosion.

What are the main advantages of Smco pot magnets?

The main advantages include high temperature resistance (up to 300°C/572°F), excellent corrosion resistance, increased holding force due to the pot design, and durability provided by the protective metal shell.