4.9 In-Situ and Dynamic Observation of Magnetic and Phase Transformation in Nd₁₅Fe₇₈B₇ Permanent Magnets at High Temperat

Nd₁₅Fe₇₈B₇ permanent magnets are known for their exceptional performance in demanding applications. In this blog, we explore how these magnets behave under high temperatures, focusing on phase transformation processes and magnetic structure evolution. Using in-situ and dynamic observation techniques, researchers gain valuable insights into the material's stability, microstructure, and performance under thermal stress.

It is appropriate to research magnetic hardening mechanism and determine use temperature of \(Nd_{15}Fe_{78}B_{7}\) permanent magnet by dynamic observation on microstructure of \(Nd_{15}Fe_{78}B_{7}\) permanent magnet at a high voltage microscope and trying to connect phase transformation and phase precipitation with macro magnetic property of the material. There are many experiment and theoretic studies on magnetic hardening mechanism of NdFeB magnets and presented a crystal structure of \(Nd_{2}Fe_{14}B\). There have two opinions on origin and mechanism of high coercivity of NdFeB permanent magnet alloy contains a little more Nd and B than \(Nd_{2}Fe_{14}B\) compound formula weight.

- High coercivity of \(Nd_{2}Fe_{14}B\) alloy is originated single - axis anisotropy.

- Coercivity of single phase \(Nd_{2}Fe_{14}B\) is very low. Coercivity of NdFeB permanent magnet alloy is mainly controlled by nucleation process of anti - magnetic nucleus. The B - rich phase, Nd - rich phase and especially Nd - rich phase among crystals of \(Nd_{2}Fe_{14}B\) with low magnetic anisotropy act as nucleation center in the center of anti - magnetic nucleation. Once the anti - magnetic nucleus formed the low magnetic anisotropy area would act as function of nails in the domain wall. Expansion of field of these nucleus further determine the strength of coercivity.

There still is another opinion on this problem that the intensity of coercivity is determined by the B - rich phase.

Nevertheless, these opinions may have somewhat limitation because all of these opinions were derived in a static state (Sagawa, Fujimura, Yamamoto, et al, 1984; Sagawa, Fujimura, Togawa, et al, 1984).

We used an 1000 kV HVM to make dynamic observations on change of microstructure of sintered \(Nd_{15}B_{7}Fe_{78}\) permanent magnet alloy at temperatures from 25°C to 600°C. It is observed that the base phase of \(Nd_{2}Fe_{14}B\) have highly dispersed precipitation, and the precipitate phase grows continually along with rising of the temperature. At 600°C the precipitation becomes polycrystals. We also observed that aberrance occurs in diffraction patterns of B - rich phase at 332°C and

Nd - rich filmy belt in the boundary of crystals become wider proportionally along with rising of the temperature (Ping, Li, Ma, Pan, et al, 1985; Pan, 1986).

Specimen Preparation and Experimental Methods for High-Temperature Observation of Nd₁₅Fe₇₈B₇

The alloy was prepared by using a casting piece composed of high purity neodymium, high purity boron and high purity iron; and then pulverized the casting piece into powder of 3.2 μm in medium of toluene. The powder was formed under a 1.5 T magnet field and sintered for one hour at 1100°C, then placed for aging at a lower temperature and quenched to room temperature as specimen for electron microscope.

The sample described above was sliced to into lamellae of 0.25 mm in the direction being vertical to \(c\) axis and thinned mechanically to 0.025 mm. Then the lamella was electrolyzed to open a hole basically in an electrolyte of 20% perchloric acid and 80% glacial acetic acid and finally be thinned and cleaned on ionic thinning device. Then the specimen was ready for observation.

Observation of specimen film was conducted in JEM - 1000 HVM. The operation voltage was 1000 kV, the output voltage was 185 V and the electrical current was 6.6 A. Vacuum was kept as \(2.13\times10^{-4}\) Pa (equivalent to \(1.6\times10^{-5}\) Torr), after adding liquid nitrogen the vacuum was adjusted to \(9.33\times10^{-6}\) Pa (equivalent to \(0.7\times10^{-7}\) Torr). Ionic beam was 10 μA. The specimen was then inserted into the side - insertion type heating dish of JEM - 1000 and observed by electronic microscope in the condition of room temperature and heat condition.

Microstructure and Crystal Boundary Phases in NdFeB Permanent Magnets

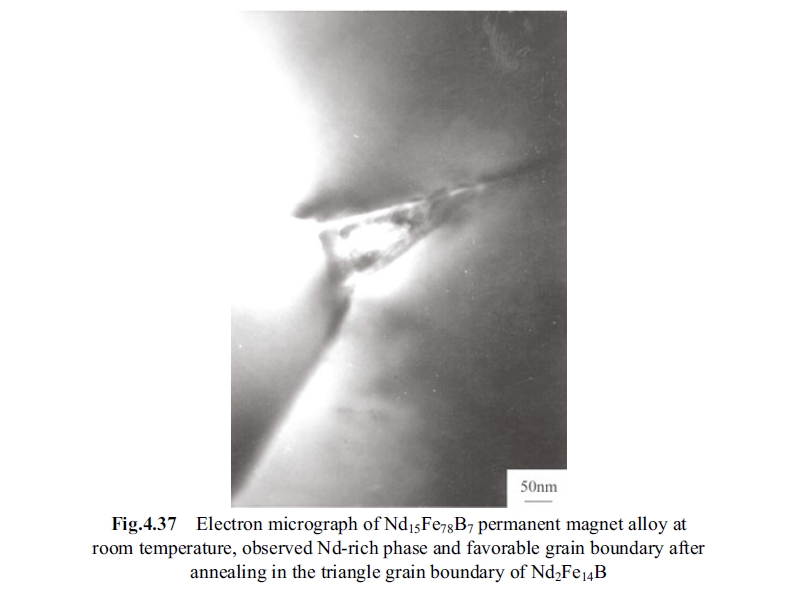

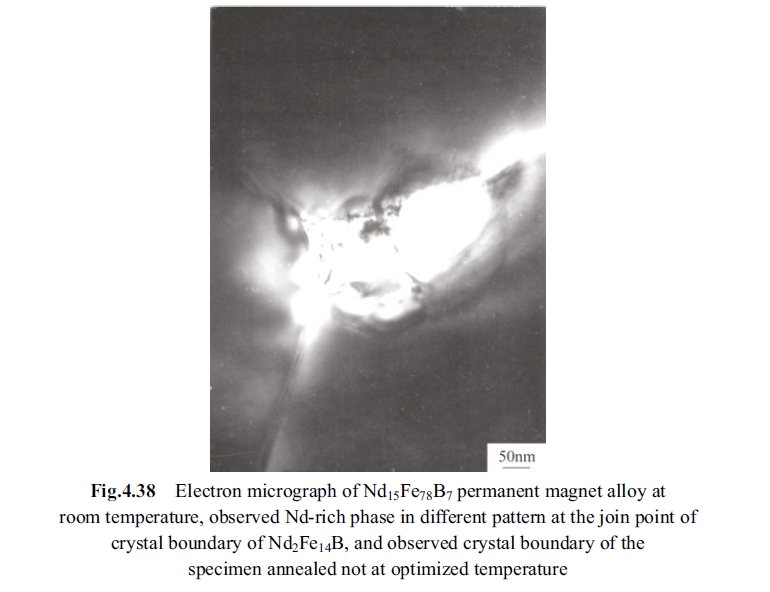

Many types of crystal boundary exist in NdFeB permanent magnet: the 1st type of crystal boundary is flat and clean; ternary and multi - component alloy have this type of crystal boundary uniformly as shown in Fig. 4.37. Enriched materials of one or more components exist in the crystal boundary. It was confirmed to be enriched neodymium by electronic diffraction. The enriched neodymium has a cubic (fcc) structure which was testified by analysis using energy spectrum. The grain boundary becomes clean through a proper annealing temperature system. The 2nd type is a multiphase crystal boundary; some even form big neodymium enriched clusters or multiple neodymium enriched clusters, as shown in Fig. 4.38. There still exists pectinate or stria lattice shapes contrast inside of NdFeB base grain boundary by adding gallium, that is analyzed as iron enriched component by energy spectrum.

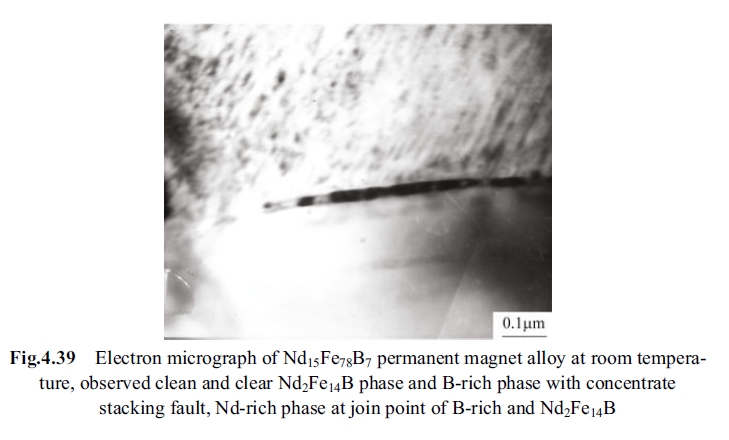

Alloy \(Nd_{15}Fe_{78}B_{7}\) generally has magnetic phase of \(Nd_{2}Fe_{14}B\) and Nd - rich phase, and a little \(\alpha - Fe\) (Fig. 4.39). Alloy containing gallium and niobium has Ga - rich phase and \(Fe_{2}Nb\) phase (Laves phase) without exception. The ternary eutectic temperature of the above mentioned 3 types of phase has big difference in comparison with the melting points of neodymium and iron; and there is a deep eutectic tendency by holding an out of order liquid structure to room temperature after aging and cooling. Nd - rich phase distributes unevenly. This inhomogeneous distribution is related to uneven cooling. Eutectic components (\(Nd_{2}Fe_{14}B\), \(Nd_{1.1}Fe_{4}B_{4}\) and Nd - rich phase) are enriched as an out - of - order deep eutectic state, such as the magnetic phase of NdFeB multi - component alloy containing niobium and gallium, and its magnetic phase becomes \(Nd_{2}(Fe, Ga)_{14}B\), \(Nd_{2}(Fe, Nb)_{14}B\), \(Fe_{2}Nb\), …, en - riched in a form of the out - of - order deep eutectic status.

Coercivity of NdFeB alloy is not high after sintering. And the coercivity may be doubled by annealing at a temperature range of 550 - 650°C. Effect of annealing behaves on the crystal boundary that result in homogenization of the neodymium enriched boundary and Nd - rich phase. Crystallization of deep eutectic structure results in that the neodymium enriched particles to form a dense distribution of granular material in cross coign of crystal boundary, and sometimes represents crystal nucleus of \(Nd_{2}Fe_{14}B\) that make the around lean iron also form Nd - rich phases. Iron content of \(Nd_{2}Fe_{14}B\) is the maximum in NdFeB magnetic alloys. The base phase contains a certain solid solute iron and a long time annealing lead to dissolution of iron atoms of \(Nd_{2}Fe_{14}B\), that causes modulated decomposition on \(Nd_{2}Fe_{14}B\) (Fidler, Luo, 1985).

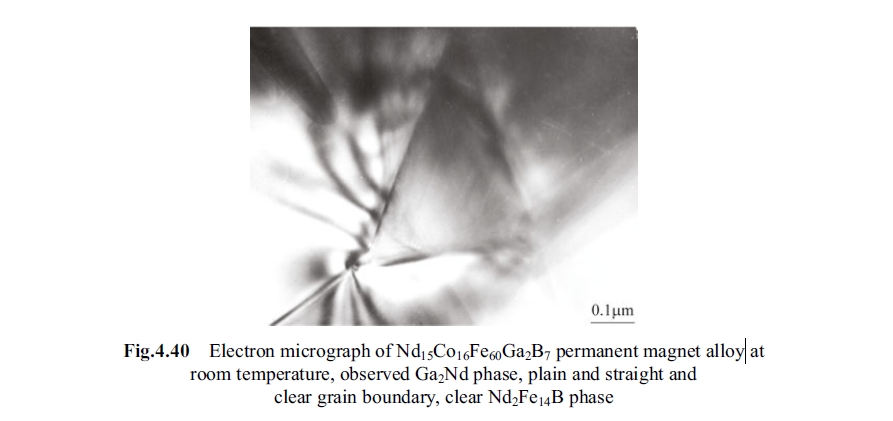

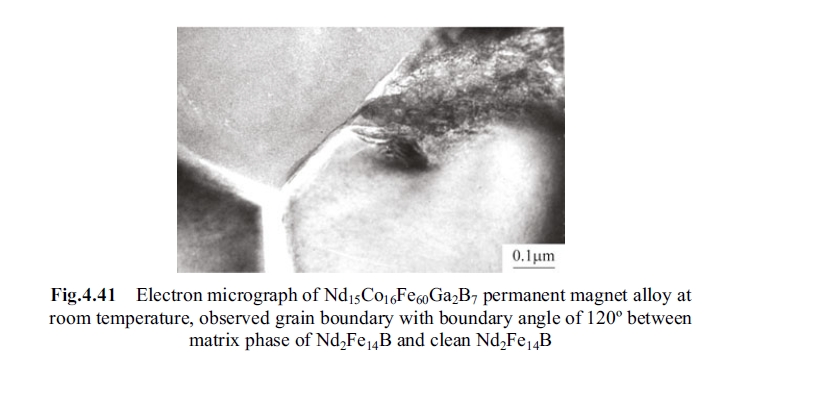

Composition of Nd - rich phase is complicated but it acts an important function on magnetic hardening of sintered NdFeB alloy. The typical Nd - rich phase is of a twin - hexagon structure, its lattice constants are \(a = 0.365\ nm\), \(c = 1.180\ nm\), the neodymium atomic fraction occupies 97% and the balance is iron atoms. The bright belts in Fig.4.40 and Fig. 4.41 surround particles of \(Nd_{2}Fe_{14}B\). Its atomic proportion is Nd 75%, Fe 25% and the ratio of Nd to Fe is around 3.5 to 1.2 in the Nd - rich phase.

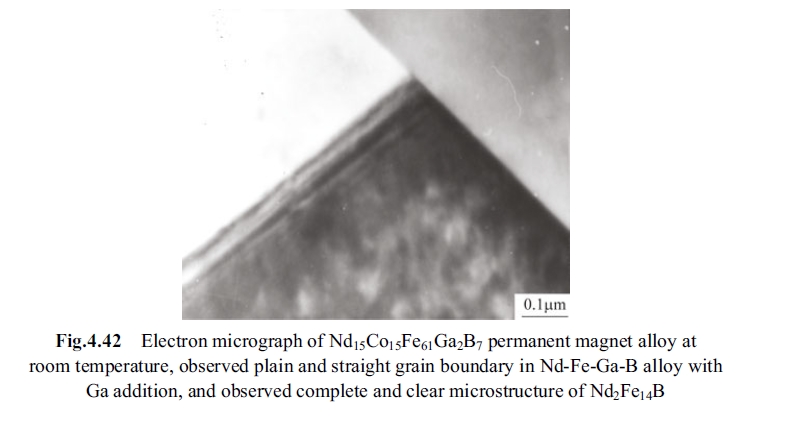

\(GaNd\), \(Ga_{2}Nd\) and \(Ga_{3}Fe_{11}Nd_{6}\) phases exist in the crystal boundary and the base phase of \(Nd_{9}Fe_{60}Co_{16}Ga_{3}B_{2}\) have orthorhombic system (\(a = 0.44\ nm\), \(b = 1.13\ nm\), \(c = 0.42\ nm\)), hexagon system and square system, respectively. It can be seen from Fig. 4.41 that the crystal boundary is not clean and has mixtures of Nd - rich phase and Ga - rich phase. Its annealing temperature is \(590^{\circ}C\) on the low side. The Fig.4.42 presents a related clean phase of crystal boundary of gallium containing NdFeB alloy. Ga - rich phase (in a triangle shape and embedded to base phase) has an integrated flat boundary with a black meddle but a bright sides. This alloy possesses high coercive field intensity.

High-Temperature Phase Transformation of the B-Rich Microstructure in NdFeB Magnets

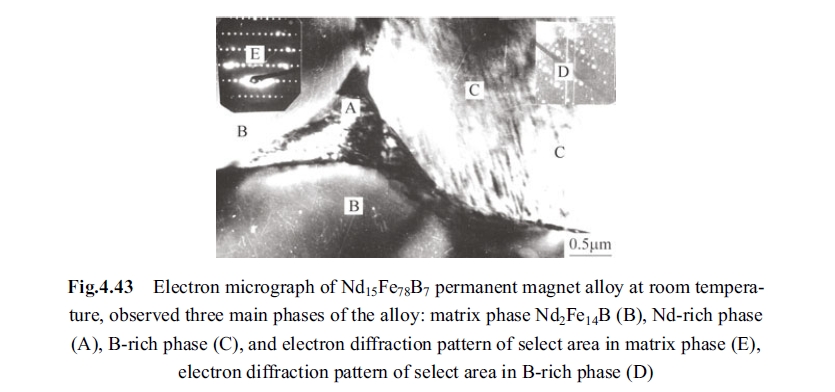

Fig. 4.43 shows electronic microscope photograph of sintered \(Nd_{15}B_{7}Fe_{78}\) specimen at room temperature. In the figure section C represents B - rich phase (\(Nd_{1.11}Fe_{4}B_{4}\)), section D represents electronic diffraction pattern of selected area of section C. We can see that: (1) the B - rich phase is clamped among base phases of \(Nd_{2}Fe_{14}B\), and, is close to Nd - rich phase; (2) Crystal defect, layer dislocation and plane defect exist inside of the B - rich phase, which can be seen in the section C; (3) character of layer dislocation is of certain orientation that exhibits bright and dark striae alternately. The B - rich phase accounts for a volume fraction of 5% - 8% in permanent magnetic alloy of \(Nd_{15}B_{7}Fe_{78}\) so that it may not be found easily in electronic microscope like base phase of \(Nd_{2}Fe_{14}B\) and Nd - rich phase. It would be found more difficultly if the specimen film be thinned excessively. Therefore, using an observable thick film under 1000 kV HVEM made the observation experiment of B - rich phase succeeded, and that becomes able to observe the layer dislocation and plane defect of striae with a certain orientation; (4) it can be seen that electronic diffraction pattern of selected area appears reciprocal point elongated phenomenon. The reciprocal point elongated phenomenon at room temperature is most possibly related to amplitude modulation of high temperature phase. We derive the reciprocal plane from (310) and (031) and calculate out its crystal lattice parameter \(a_{0}=0.7128\ nm\), \(c_{0}=0.3894\ nm\). This result is close to the data of reference that gave \(a_{0}=0.7128nm\), \(c_{0}=0.3894\ nm\) for the \(Nd_{1.11}Fe_{4}B_{4}\) (Givord Moreau, Tenaud, 1985). Iron and boron in ternary compound of \(Nd_{1.11}Fe_{4}B_{4}\) together compose a substructure in square symmetry, the same as the substructure composed of neodymium atoms. All of these struc-

tures are described using Pcmn orthorhombic space group (\(a_{0}=b_{0}=0.7117nm\), \(c_{0}=0.3507nm\)). All parameters of sublattice of B - rich phase (\(Nd_{1.11}Fe_{4}B_{4}\)) in NdFeB permanent alloy can be computed out as follows by using electronic diffraction pattern of selected area in C location of Fig. 4.43.

| Name of sublattice | \(a_{0}\) | \(c_{0}\) |

|---|---|---|

| Fe sublattice | 0.7182 nm | 0.3894 nm |

| Nd sublattice | 0.7100 nm | 0.3528 nm |

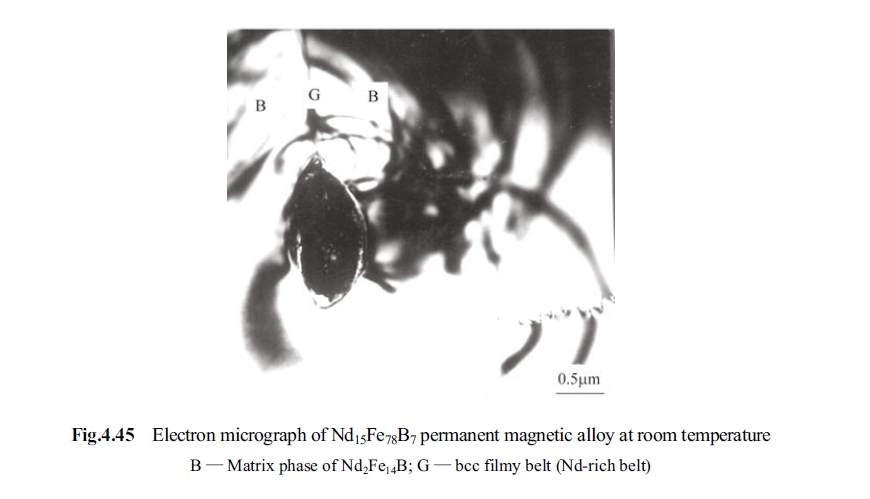

This specimen was heated in 1000 kV electronic microscope and dynamic observe the precipitation process (made video record for dynamic observation in the same time). When the temperature raised to \(322^{\circ}C\) micrograph of B - rich phase changed largely compared with that at the room temperature, as shown in Fig. 4.44. Precipitated black block appears inside of B - rich phase and oxidation occurs in the dislocation direction of precipitated black block. Direction of dislocation striae in other place does not be so obvious and so clear as that at room temperature. Fig.4.45 changed obviously compared with Fig.4.43. The atomic ordered temperature of \(Nd_{1.11}Fe_{4}B_{4}\) is 14K and its magnetic intensity is strongly abnormal. The reference reported that at \(322^{\circ}C\) there is another abnormity in magnetic intensity (Givord, Moreau, Tenaud, 1985). This opinion is consistent with phenomenon by this dynamic observation that the micrograph of B - rich phase has big change at \(322^{\circ}C\).

Transformation of the Nd-Rich Filmy Belt at the Crystal Boundary of Nd₁₅Fe₇₈B₇ at Elevated Temperatures

It was discovered at first that there is Nd - rich filmy belt among crystals of

\(Nd_{2}Fe_{14}B\) at room temperature (Fig. 4.45). It was found further that the Nd - rich filmy belt only exists among crystals of \(Nd_{2}Fe_{14}B\) and between B - rich phase and \(Nd_{2}Fe_{14}B\) phase in a serious and careful observation.

It was observed that the Nd - rich filmy belt is widened when the temperature

rose to \(140^{\circ}C\), as shown Fig. 4.46. By continually raising temperature to \(312^{\circ}C\) (the Curie temperature of this alloy) we found the Nd - rich filmy belt is further widened, as shown in Fig. 4.47. It can be seen from Fig. 4.47 and Fig. 4.48 that the particles inside of the filmy belt are inhomogeneous but the whole filmy belt is very regular. When the temperature was raised to \(600^{\circ}C\) and held for 30 min, highly dispersed precipitates appears inside of base phase but the filmy belt keeps intact without any dispersed precipitates, as shown in Fig. 4.49.

Phase Transformation of the Nd₂Fe₁₄B Base Phase in Nd₁₅Fe₇₈B₇ Alloy at High Temperature

Section B in Fig.4.43 is the micrograph of \(Nd_{2}Fe_{14}B\) base phase of \(Nd_{15}Fe_{78}B_{7}\),

section E is electronic diffraction pattern of the selected area. That \((uvw)^* = (-101)\) can be calculated from \((010)\) and \((101)\). The crystal parameters are worked out as \(a_{0} = 0.881\ nm\), \(c_{0} = 1.203\ nm\), that is similar to \(a_{0} = 0.879\ nm\), \(c_{0} = 1.219\ nm\) reported by reference (Givord, Moreau, Tenaud, 1985).

It can be seen from Fig.4.43 that there has not any elaborate texture, and neither has crystal defect inside of \(Nd_{2}Fe_{14}B\) at room temperature.

The dynamic observation of precipitation process did not find any precipitate below \(280^{\circ}C\); by heating this specimen; at \(280^{\circ}C\) the specimen began to appear precipitates; at \(312^{\circ}C\) it was observed clearly that a highly dispersed precipitation phase bestrews to all visual field, and a diffraction ring of polycrystals appears on diffraction pattern. The precipitates are growing continually along with rising temperature and cause a change in crystal lattice at temperature of \(500^{\circ}C\). \(Nd_{2}Fe_{14}B\) precipitated at \(500^{\circ}C\), as shown in Fig. 4.48 and Fig. 4.43 D. Precipitates of \(Nd_{2}Fe_{14}B\) crystal granule are shown in Fig. E.49 when temperature was raised to \(600^{\circ}C\). It can be seen from the figure that the precipitates grow up rapidly. The diffraction pattern of base phase appeared many more polycrystalline rings compared with that at \(300^{\circ}C\) or \(500^{\circ}C\), as shown in section E of Fig. 4.49. The electronic diffraction pattern of selected area of precipitate phase is shown in section F of Fig. 4.49, which can be seen as polycrystalline rings entirely. This indicates that the single crystals of \(Nd_{2}Fe_{14}B\) in the \(Nd_{15}Fe_{78}B_{7}\) precipitated to be polycrystals and the precipitate is in a scale of the tenth nm.

The massive specimen was heated in the sintering furnace as per the above mentioned heating sequence, and held at \(600^{\circ}C\) for 40 min, quenched and remagnetized, and then measured its magnetism. As the result the coercivity is not only lowered but increased slightly. It is found in dynamic observation that the dislocation existing at room temperature is reduced somewhat when raising temperature to \(140^{\circ}C\). Most of the dislocation is reduced at \(312^{\circ}C\), and almost all of the dislocations became unobservable at \(600^{\circ}C\). This observation reveals the function of clearing up stress by low temperature aging at around \(600^{\circ}C\).

It is discovered in the dynamic observation that crystal boundary among \(Nd_{2}Fe_{14}B\) is still clear even if heating to \(500^{\circ}C\).

For \(Nd_{15}Fe_{85 - x}B_{x}\) if \(x = 11\), \(Nd_{2}Fe_{14}B\) quantity descends 5%. It does not affect intrinsic coercivity, but enhance, NdFeB alloy quantity and the saturation magnetization intensification, properly controlling boron (B) content and alloy ingredient, properly increasing Fe enhance \(Nd_{2}Fe_{14}B\) comprehensive effective (Pan, Zhao, Li, et al, 2011).

Conclusions: Key Findings on Phase and Magnetic Behavior in High-Temperature NdFeB Magnets

- Sintered NdFeB permanent magnetic alloy with unexampled high magnetic

energy product is due to good square symmetrical phase of \(Nd_{2}Fe_{14}B\) (base phase) formed by adding boron and a proper amount of Nd - rich phase and B - rich phase. Where the base phase of \(Nd_{2}Fe_{14}B\) made the biggest contribution to magnetic energy product. NdFeB alloy has a big magnetic anisotropy through function of crystal field because \(Nd^{3 +}\) possesses track magnetic moment. Furthermore, split of crystal field of rare earth 4f energy grade is the source of intrinsic magnetic anisotropy in \(Nd_{2}Fe_{14}B\). All of magnetic moments of neodymium and iron are parallel to \(c\) axis and the magnetic moment array is ferromagnetic. However, the square symmetry is broken because of rising temperature. The precipitate has been observed at \(280^{\circ}C\), and that the original non - defective base phase of \(Nd_{2}Fe_{14}B\) appears defects due to precipitation of tiny polycrystals. These defects become anti - magnetic nucleation center that results in degradation of coercivity.

2. One of the functions by aging for 1 h at \(600^{\circ}C\) is to eliminate internal stress. It is observed that dislocations disappeared along with rising of temperature in dynamic observation.

3. bcc filmy belt of Nd - rich phase surround homogeneously \(Nd_{2}Fe_{14}B\) phase, Nd - rich phase and B - rich phase in a specimen being aging for 1 h at \(600^{\circ}C\). It is observed in the dynamic observation that the bcc filmy belt is widened proportionally along with rising of temperature, meanwhile the intensity of coercive force degrade with rising of temperature and the coercivity degrade to \(0^{\circ}C\) at \(312^{\circ}C\). The bcc filmy belt widens regularly and proportionally at rising temperature up to \(600^{\circ}C\). And that there are polycrystalline precipitates fulfilling the field of vision in a size of tens nm on \(Nd_{2}Fe_{14}B\) but the bcc filmy belt appears no precipitate. This fact indicates that bcc filmy belt make no contribution to the coercivity and may not belong to hard magnetic phase.

4. B - rich phase in sintered NdFeB permanent magnetic alloy has crystal defects at \(25^{\circ}C\). There are two type of lattices: ferrous sublattice (\(a_{0}=0.7128nm\), \(c = 0.3894nm\)) and neodymium sublattice (\(a_{0}=0.7100nm\), \(c = 0.3528nm\)).