2.7 Magnetism of SmCo₅ Permanent Alloy Across a Wide Temperature Range (1.5-523 K)

Magnetism measurement of rare earth permanent magnetic alloy was to place the specimen firstly under magnetic field being above the \(4\pi M_s\) of the specimen and then the specimen was magnetized to saturation. Afterwards the magnetized specimen was placed into electromagnetic iron of magnetic measurer to measure demagnetization curve using magnetic parameter measurement apparatus (Zhang, Cheng, Zhang, 1982). The demerit of this magnetism measurement method is unable to measure intrinsic magnetism of the specimen with a magnetic field intensity above 2.1 T because normal electromagnetic iron can only produce a magnetic field intensity about 2.0 T. Therefore, for a rare earth permanent magnetic alloy with an intrinsic coercivity above 2.1 T this measurement can not describe its whole intrinsic magnetic measurement curve. In order to study magnetic performance of rare earth permanent magnetic alloy at low temperature and to widen application scope of the rare earth permanent magnetic alloy, we adopted advanced instrument with ultra strong magnetic field produced by superconductive magnet which is vibrant specimen magnetic intensity apparatus to measure and study the magnetic speciality. This section provides magnetism of rare earth permanent magnetic alloy at 1.5 - 523 K and one type of magnetism measurement and study method to study magnetism of magnetic materials from high temperature to deep low temperature and to avail application of the material.

Specimen Preparation, Magnetic Measurement Apparatus, and Experimental Methods

This experiment prepared a few types of specimens with the specific composition (in mass fraction) were 36.9% Sm + 63.1% Co (for specimen No.1) and 37.5% Sm + 62.5% Co (for specimen No.2). Manufacturing technique was as follows: enclosed the prepared material into arc furnace for melting; the ingot after melting was milled from coarse, middle and fine to about 5μm; the powder was molded under magnetic field and sintered at 1150°C for 1.5h; afterwards the temperature was lowered to 950°C and held for 1h, and quenched to room temperature; then the specimen was available for measurement (Pan, Jin, 1990; Pan, Ma, Li, 1993; Pan, 1996).

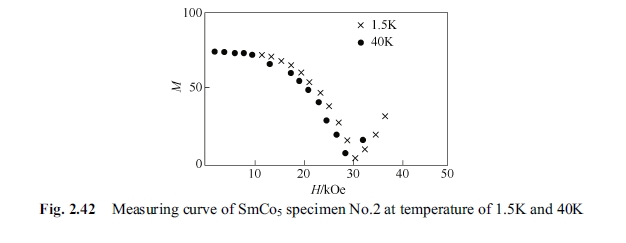

Magnetic measurement instrument and experimental method: vibrant specimen magnetization intensity apparatus for measurement at 1.5K, 40K; magnetism parameter measurement apparatus of rare earth magnet made in Baotao Rare Earth Research Institute for measurement at temperature from -196°C to 250°C, measurement condition 50Hz single cycle pulse magnetic field.

Magnetic Behavior of SmCo₅ Permanent Alloy at Extremely Low Temperatures (1.5 K and 40 K)

- Measured curve using magnetic parameter measurement instrument at room temperature (25°C) is shown in Fig. 2.40. The magnetic performance is as follows: specimen of 36.9% Sm (wt.) + 63.1% Co (wt.) (specimen No.1), measurement data are \(B_r = 0.92\) T, \(_{m}H_c= 1592.00\) kA/m, \(_{b}H_c = 716.40\) kA/m, \((BH)_{max}= 167.16\) kJ/m³.

-

2.

Measuring result in ultra conductive magnetic field using vibrant specimen magnetic intensity apparatus: measured \(M = 19.36\) emu/g at temperature of 1.49 K in center of apparatus; intrinsic coercivity \(_{m}H_c = 30,009\) Oe (2388.72 kA/m), its curve refers to Fig. 2.41, its performance refers to Table 2.7.

Demagnetization Curve and Magnetic Parameter Measurements of SmCo₅ at -196°C to 250°C

Measurement sequence:

\(25^{\circ}C\rightarrow100^{\circ}C\rightarrow150^{\circ}C\rightarrow200^{\circ}C\rightarrow250^{\circ}C\rightarrow\) \(25^{\circ}C\rightarrow - 60^{\circ}C\rightarrow - 196^{\circ}C\rightarrow25^{\circ}C\)

Fig. 2.43 showed demagnetization curve at 7 different temperatures. The measurement was carried out as per sequence from room temperature (\(25^{\circ}C\)) to high temperature (\(250^{\circ}C\)), return to room temperature (\(25^{\circ}C\)), and then to low temperature (\(-196^{\circ}C\)) and again return to room temperature (\(25^{\circ}C\)). The measured demagnetization curves can be superposable in all, which indicated that there was not any magnetic irreversible loss caused by variation of temperature in above mentioned temperature condition.

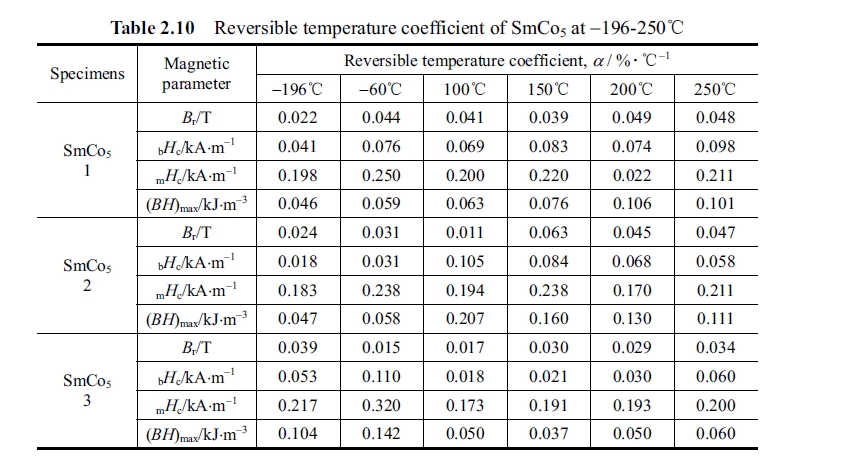

Reversible Temperature Coefficient of SmCo₅ in the Temperature Range of -196°C to 250°C

Reversible temperature coefficients of SmCo5 at −196 - 250 °C are shown in Table 2.10.

Coercivity of SmCo₅ Permanent Magnets at High Temperatures (475-1000°C)

Coercivity of SmCo5 was measured using magnetic parameter measurement apparatus after annealing at 475°C, 500°C, 650°C, 750°C, 850°C, 900°C and 1000°C, the measured coercivity value is listed in Table 2.11. It can be seen that coercivity of all specimens are the lowest at 750°C, and enhanced again at 850°C, 900°C and 1000°C; the coercivity of specimens No.3 and No.6 appeared higher at a given temperature and higher comparatively also at 750°C. The experiment data indicates that the coercivity is the lowest at 750°C at temperature range from 475°C to 1000°C. The degradation of \(H_c\) is related to coercivity of the specimen itself.

Discussion: Insights into Temperature Effects on SmCo₅ Magnetism

The following discussion is carried through based on above mentioned study:

- Magnetic performance of SmCo5 permanent magnetic alloy decreases along with rising of temperature and increases along with lowering of temperature, and has good reversible character.

- SmCo5 permanent magnetic alloy does not exist low temperature irreversible loss by measuring at low temperature (Zhang, Cheng, Zhang, 1982; Pan, Jin, 1990; Pan, Ma, Li, 1993; Pan, 1996; Zhao, 1989).

- It is obtained from magnetic measurement of multi specimens and study that magnetic irreversible loss is related to the height of coercivity of the alloy and some steps out of required criterion of technique in preparation.

- SmCo5 permanent magnetic alloy has good magnetic performance at low temperature of 1.5K and 40K and is of good application capability (Chen, Li, Wang, Cao, Ma, Pan, 1997; Pan, et al, 1990; Tang, Feng, Luo, Pan, 1994; Tang, Pan, Luo, 1994).

- It can be seen from Table 2.11 that degradation of coercivity of the SmCo5 permanent magnetic alloy with a higher intrinsic coercivity is smaller than that of the alloy with a lower intrinsic coercivity after annealing at 750°C. This indicates that to improve thermal stability of SmCo5 alloy it needs to improve coercivity in preparation technique (Pan, Zhao, Ma, 1989; Geng, Ma, Pan, et al, 1991; Pan, Xiao, 1989).

- In comparison between \(_{b}H_c\) and \(_{m}H_c\) that the degradation magnitude of \(_{b}H_c\) is smaller than that of \(_{m}H_c\).

- It can also be seen from Table 2.11 that among 11 specimens only specimens No.3 and No.7 of which the coercivity was higher than that at 475°C after coercivity degradation at 750°C, and the coercivity of other specimens was lower than that at 475°C after coercivity degradation at 750°C. This indicates that for most of specimens their coercivity after annealing at 750°C can not be restored to the coercivity before annealing at 750°C.

- It can be seen from the demagnetization curve at 1.5K and 40K that the ridgdegree of demagnetization curve of SmCo5 measured at 1.5K is bigger than that measured at 40k

- In 1966, K J Strnat developed the first generation of rare earth permanent magnets- SmCo5 magnets of which magnetic energy product is about 5.1MGs·Oe, and be extended to 20MGs·Oe in 1970. In 1996, the second generation of rare earth permanent magnets- Sm2(Co, Fe)17 magnets were developed by K J Strnat. The magnetic energy product of Sm2(Co, Fe)17 magnets were 35MGs·Oe in 1980. NdFeB magnets, the third generation of rare earth permanent magnets, were developed by GE and Sumitomo in 1983, of which magnetic energy product reached 38MGs·Oe (Xu, Xie, Zhang, Huang, Xu, 2008).

Conclusions: Key Findings on Temperature-Dependent Magnetic Properties of SmCo₅

It is concluded through above mentioned study that:

- SmCo5 permanent magnetic alloy has good magnetic performance at 1.5 - 523K and has a comparatively high magnetic performance at this temperature range so that this alloy can be used in the instrument with usage range from 1.5 K to 523 K.

- The lower the temperature is the higher the magnetic performance will be. The magnetic performance at 1.5 K is higher than that at 40 K and that at 40 K is higher than that at 300 K. The higher the temperature is the lower the magnetic performance will be.

- SmCo5 permanent magnetic alloy has different magnetic performance because of the difference in samarium content. The higher the samarium content is, thus the higher the intrinsic coercivity will be and the higher the cobalt content is, the higher the saturation magnetization intensity will be, and the lower the coercivity will be comparatively. The regulation in low temperature is consistent with that in normal temperature.

- Magnetic irreversible loss is related to the height in coercivity of the SmCo5 alloy. The intrinsic coercivity of the alloy is of a good thermal stability and that its magnetic irreversible loss will be smaller. The height of the minimum coercivity degraded to at 750°C is related to the height of coercivity of the specimen.