2.2 In-Situ and Dynamic Observation of High-Temperature Phase Transformation in SmCo₅ Permanent-Magnet Alloys (25 - 750°C)

SmCo₅ Permanent Magnetic Alloys is provided with very high saturated magnetic intensity, Curie temperature and magnetic crystal anisotropy. It has been developed speedily and applied widely since it was born. Some problems have appeared along with its application and thereby brought forward a series of new subjects which are worthwhile to study in - depth.

Magnetic Measurement Techniques for SmCo₅ Permanent Magnetst

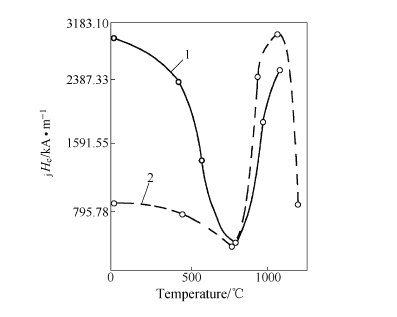

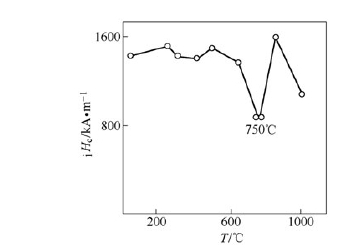

Early in 1970 Wenstendorp discovered in experiment that the coercivity of SmCo5 permanent magnetic alloy varied nonlinearly along with rising of annealing temperature, as shown in Fig. 2.1.

Fig.2.1 The relation curve of coercivity of SmCo5 permanent magnet alloy at room temperature vs annealing temperature

1—Coercivity vs sintered temperature; 2—Coercivity vs annealing temperature

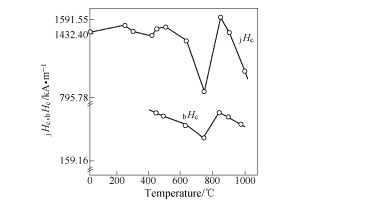

It is observed from Fig. 2.1 that the coercivity of SmCo5 was degraded to minimum after annealing at 750 °C. Afterwards the coercivity was raised along with rising of temperature over 750 °C. This regularity that the coercivity of SmCo5 varies with change of annealing temperature was verified by experiments. Author, et al. worked out experimental curve in 1981, as shown in Fig. 2.2. It can be seen that the regularity for both intrinsic coercivity and technique coercivity was consistent.

It can be seen from Fig. 2.2 that the intrinsic coercivity appeared a small peak value by annealing at 600 °C or below, but generally varied a little. After exceeding 650 °C the coercivity degraded and reached minimum at 750 °C. Annealing at 750 - 850 °C the coercivity began to rise until 850 °C at which the coercivity reached the maximum, and degraded after 850 °C. This phenomenon attracted great interesting of people who engaged with study and application of SmCo5. Thus a great lot of experimental studies were carried out, and as the significance that the study results enriched and developed the coercivity theories, and so that to provide experimental basis in practical application and to promote development of magnetic theory.

Since 1970 up to now many scholars presented their thesis related to annealing

Fig. 2.2 The relation curves of coercivity of SmCo5 alloy vs annealing temperature

(The above one of two curves shows the relation of the intrinsic coercivity vs temperature from 0°C to 1000°C. The one below shows the relation of the technique coercivity of SmCo5 samples vs temperature from 0°C to 1000°C. Both curves indicate that the coercivity goes down at 750°C and goes up at 800°C)

effect on coercivity of SmCo5. Those can be concluded to 5 sorts in accordance with their opinions.

- The annealing effect on coercivity of SmCo5 is caused by eutectoid decomposition. At 750 °C the SmCo5 decomposed into two phases of Sm2Co7 and Sm2Co17. Early in 1974, K. H. J. Buschow presented his thesis in J. Less - Common Met. in which he believed that eutectoid decomposition of SmCo5 would occur at below 800 °C, i.e., SmCo5 → Sm2Co7 + Sm2Co17. And in the same year A. Den Broeder, et al also supported the opinion mentioned above. They considered that the Sm2Co7 and Sm2Co17 phases eutectoid decomposed from SmCo5 had the magnetic crystal anisotropy was much lower than that of SmCo5. These two phases may become nucleation center on anti - magnetization domain and so that resulted in degradation of coercivity. In 1975 I. Pfeiffer, et al. and D. L. Uartin et al. considered that the SmCo5 alloy did not form SmCo5 phase at 800 °C or below.

- The annealing effect on coercivity of SmCo5 was due to precipitation of Sm2Co17 phase in which the magnetic crystal anisotropy was smaller in a quantitative level than that of SmCo5. In 1978 H. Kronmüller believed that the precipitated Sm2Co17 phase would become anti - magnetization nucleation centers to degrade the coercivity.

- The annealing effect on coercivity of SmCo5 was due to spinodal decomposition reaction. Y. C. Chuang, et al suggested in 1982 that RE2Co17, RE2Co19 and RE2Co7 derived from structure of SmCo5 phase: 3RECo5 − RE + 2Co → RE2Co17, or 4 RECo5 − Co + RE → RE2Co19. That indicated that decomposition of SmCo5 did not need fluctuation of components and formation of new phase which may lead to decline of system free energy.

- The annealing effect on coercivity of SmCo5 was due to more oxygen being

dissolved in SmCo5 at 750 °C. F. J. Den Broeder, et al. presented above opinion in 1966. Many people believed that when SmCo5 was annealing at 700 – 800 °C the precipitated Sm2Co17 phase was formed due to absorption of oxygen, which resulted in formation of Sm2O3 by oxidation of samarium and appearance of cobalt - enriched area, then so that to promote precipitation of Sm2Co17 phase.

5. The annealing effect on coercivity of SmCo5 was caused by anisotropy from heat expansion of SmCo5. K. Kumar, et al. suggested in 1978 that heat expansion among crystal granules naturally caused different heat stress and the difference in cooling speed also caused different heat stress.

Study on the subject of annealing effect of SmCo5 and make it clear are of significance both in practical application and theory. For this purpose Shuming Pan, Hanmin Jin, et al. studied this subject from 1980 to 1983 by using photoelectron spectrum, autoclectron oblivion technology, X - ray diffraction and 1000 kV HVEM dynamic observation technique, and combining magnetic measurement and computing magnetic anisotropy of Sm3+ in imperfect structure of Sm2Co17 precipitate phase. As the result they presented a new viewpoint different with above mentioned 5 opinions and formed new theoretic opinion.

Sample Preparation and Experimental Methods for Studying SmCo₅ Magnets

Preparation process

The SmCo5 sample for experiment was confected by using alloy melting method, i.e., melted in arc furnace under argon protection atmosphere. The ingot was crushed to about 5 μm by vibrant ball grinder (protected from oxidation in organic medium) and orientation formed under 1.5 T magnetic fields. The formed sample was sintered at 1,120 °C for 1 hour and cooled to 900 °C in a speed of 0.8°C/min and held. Afterwards the sample was quenched to room temperature. The specimen after heat demagnetization was machined to required specification for observation.

Method for antielectron oblivion experiment

The antielectron oblivion longevity (\(\tau\)) and Doppler widened linear parameter (\(S\)) of oblivion radicalization were measured for above mentioned specimen at room temperature.

The longevity spectrum instrument is a quick and slow coincident system, and its time resolving power (FWHM) for 60Co radiate source is 260 ps. Each specimen was measured 2 - 4 times repeatedly. Total countered number for each measurement was about 8×105. Measured data was treated by index fitting method and analyzed \(\tau_{1}\) and \(\tau_{2}\) two longevity components. Among them the long longevity group \(\tau_{2}\) has a comparative intensity was very small, that was considered to be caused by source effect. Thus the short longevity group (\(\tau_{1}\)) was taken as the average longevity of antielectron obliterated in integral crystal lattice and defect of specimen. When new vacancy defects occurred, the longevity of antielectron would be increased because density of electron decreased in defect.

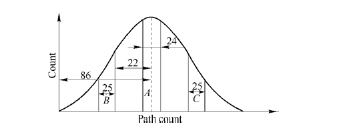

The Ge(Li) \(\gamma\) spectrum instrument for \(\gamma\) measurement and \(S\) parameter has a resolving power (FWHM) of 1.45 keV. Each specimen was measured 3 – 5 times repeatedly and total countered number for each measurement was about \(7\times10^{5}\). \(S\) parameters were computed directly by online computer. In this experiment the \(S\) parameter was defined as:

\(S = A/(B + C)\)

where \(A\) is counter number of 24 paths in center of the energy spectrum of obliterated radicalization; \(B\) and \(C\) are counter number taken from 25 paths in two wings of the spectrum. As shown in Fig. 2.3 that energy corresponding to each path was 75eV. The more defects the specimen has the smaller the average electron momentum will be in the defect location. As the result the counter path in center will be increased and the counter path in wings will be decreased so that the \(S\) parameter will be big.

In the measurement the non - carrier \(^{22}\text{Nd}\) clamped between polyester films were taken as antielectron source, and the source was clamped between two same specimens and its strength was 5 \(\mu\)C.

Fig. 2.3 The diagram of the definition of S-factor of Doppler broadening

Influence of Annealing Treatment on the Coercivity of SmCo₅ Magnets

All specimens were SmCo5 magnet with samarium enriched equivalent amount of component quenched from 900 °C besides those specially explained. Magnetization measurement was carried out at room temperature. The magnet was cut to 15.5×7.5×0.95 lamellas with its easy magnetisable axis paralleling with 7.5 mm rhombohedra. After being polished using metallographic paper each of two specimens were annealed at 710 °C for 4 min, 8 min, …, 60 min and 80 min at protection of argon atmosphere and quenched, and then measured the demagnetized curve. These loop - lines were makeup by superposition on a big loop of high coercivity with small loop - lines of low coercivity. The latter disappeared after surface electrolytic polishing by dozens microns. It is obviously that those small loop - lines come from surface cobalt enriched layer formed by preference oxidation of samarium (Pan, et al, 1983; Fidler, et al, 1980).

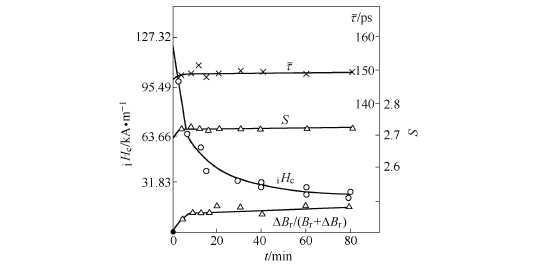

Fig. 2.4 indicates intrinsic coercivity after electrolytic polishing and the relation between the comparative volume \(\Delta B_{r}/(B_{r}+\Delta B_{r})\) of cobalt enriched surface layer phase and aging time, where \(\Delta B_{r}\) and \(B_{r}\) are remanence of small loop - line and big loop - line before polishing. The intrinsic coercivity is not very sensitive to existence of cobalt enriched layer, which explains that the domain wall is pinned strongly by crystal boundary. The degradation of coercivity is caused by decrease in nucleation field of antimagnetic nucleation in crystals.

Fig. 2.4 Annealing time dependence of \(_{i}H_{c}\), \(S\) and \(\Delta B_{r}/(B_{r}+\Delta B_{r})\), in which annealing temperature is 750°C

The antielectron oblivion longevity (\(\tau\)) and Doppler line widening parameter \(S\) were measured for this specimen group (Fig. 2.4), among which value of the latter indicated widening extent of curve. That the \(\tau\) and \(S\) did not varied with passing of time is not consistent with the result measured at room temperature. This phenomenon indicated that there was no vacant defect appeared in process of aging at 710 °C.

Experiments for influence by aging on coercivity were made for mass specimens at different temperature within 25 - 1000 °C and aging 1 hour. That obtained the similar results. The intrinsic coercivity drastically degraded by annealing at 750 °C for short time and aroused at 900 °C, seeing Fig. 2.5.

Fig. 2.5 The relation of the intrinsic coercivity \(_{i}H_{c}\) vs annealing temperature

(The composition of the specimen is 37.66%Sm, 62.34%Co. It is showed that the intrinsic coercivity has the lowest value at 750°C)

In-Situ and Dynamic Observation of SmCo₅ Phase Transformation Using 1000 kV HVEM Under Heating Conditions

The specimen with constituents of Sm 37.66% (wt), O₂ 1.2% (wt) was sliced into lamellae in direction perpendicular to magnetisable axis and then was ionic thinned to film for observation by using electronic microscope. The used microscope was JEM - 1000 type with 1000 kV, the vacuum was 1.6×10⁻⁵ Pa (1.2×10⁻⁷ Torr) and after addition of liquid nitrogen the vacuum was 9.3×10⁻⁶ Pa (0.7×10⁻⁷ Torr).

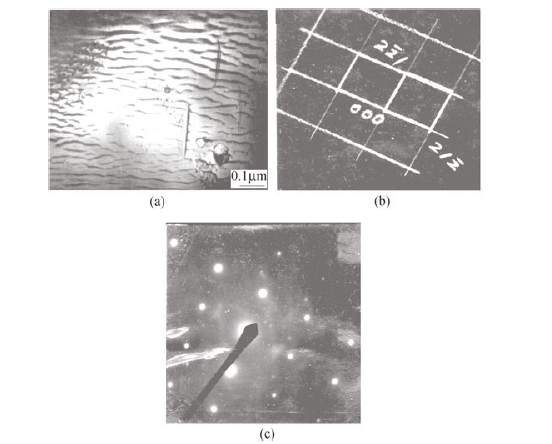

Observation by JEM - 1000 HVEM at room temperature

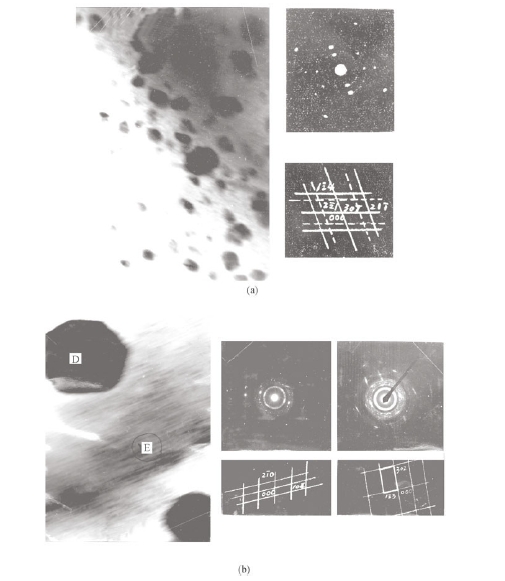

The observation result and analysis at room temperature: the Fig. 2.6(a) shown electronic micrograph of SmCo5 alloy at room temperature that most of area in the electron micrograph did not have precipitate but once in a while may saw a few defect such as layer dislocation and in the same area also observed precipitated phase. Fig. 2.6(b) and Fig. 2.6(c) were electronic diffraction pattern and indexes of the matrix which was determined as SmCo5.

Fig. 2.6 The microstructure of SmCo5 permanent magnet alloy at room temperature

(a) The picture of the microstructure under electron microscope of SmCo5 permanent magnet alloy at 25°C; (b) Indexing of electronic diffraction pattern of SmCo5 permanent magnet alloy at selected area under 25°C; (c) The electron diffraction pattern of SmCo5 permanent magnet alloy at selected area under 25°C

The in situ and dynamic observation on phase transformation at high temperature by JEM - 1000 HVEM

This section revealed the whole process of phase transformation of SmCo5 alloy from room temperature to 950°C, including driving force, transformation resistance, homogeneous and heterogeneous nucleation, growth process, etc.

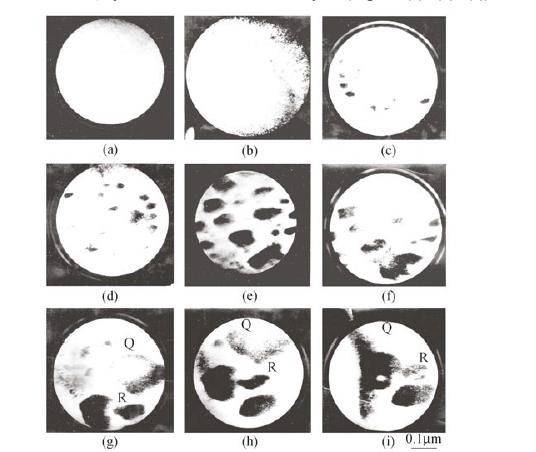

A. Observation on experiment result

The specimen of SmCo5 was heated in the side inserting type heating dais. The dynamic observation found that there is no precipitate in the selected area through tilting the rotation dais in many times. The SmCo5 specimen did not appeared any precipitates under heat activation before 350°C. After raised to 420°C rapidly there was highly dispersed small precipitate points which was not clear even after being magnified to 20000 times. When the temperature reached 420°C and held for 2 min the highly dispersed precipitates could be observed clearly and fulfilled all of the view in the place originally had not any precipitate. And being held for 40 min continually the precipitate phase would grow up to dozens nanometers, which was Sm2Co17 by electronic diffraction analysis (Fig. 2.7(a), (b), (c)).

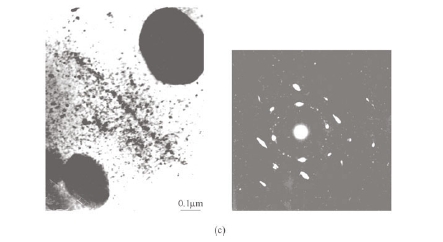

G. Observation and analysis on phase of Sm2Co7 precipitated from the matrix phase of SmCo5

In the phase of Sm2Co17 fulfilled the vision there were big piece of hexagon, small piece of round \(D\) and Sm2Co7 phase of striation \(E\), seeing Fig. 2.9 (a), (b). And it was observed specially that the phase of Sm2Co7 located among big pieces of hexagon spots of Sm2Co17 transformed to be Sm2Co17 phase (from the Sm2Co7

Fig. 2.7 The microstructure of SmCo5 specimen under JEM - 1000 ultra - high voltage electron microscope

(Dynamic in situ observation of the high temperature phase transition, e.g. precipitation of Sm2Co17-phase, upgrowth, coarsening, merging while heating temperature reaches 750°C from 25°C. Multi - defect area in Sm2Co17-phase appears as (a) to (i))

C. Variation of free energy in phase transformation and power of nucleation

The new phase of Sm2Co17 precipitated from SmCo5 matrix phase grown 1 - 2 times in 8 min. What is the decisive factor for growth of the new phase? The transfer process of phase boundary is the growth process of new phase. Thus, the speed of phase boundary influenced the growth speed of new phase. On the boundary there is difference in concentration between the matrix phase and the new phase, or says, there is an equilibrium concentration. Difference in concentration existed in the matrix phase where the diffusion is caused by the concentration difference. The growth of new phase is aim to restore equilibrium concentration in the boundary, and that the atoms diffusion speed determines growth speed of the new phase.

It was observed dynamically that precipitation of Sm2Co17 phase from SmCo5 matrix phase was comparatively slow but after holding at 420°C the speed of phase transformation became the highest. This was because that when the new phase of Sm2Co17 precipitated at the beginning, the nucleus was very small, volume increment of phase transformation was not big by linear growth, and the grown - up of the nucleus caused volume increase in three - dimension. The dynamic variation process of (f), (g), (h) and (i) in Fig. 2.7 is the new phase gradually grown up to the terminal stage. That mutual attraction, mutual contact, aggregation and phase transformation existing among new phase points again make the speed lowered gradually.

Nucleation speed of new phase varies along with time and interface of phase varies along with time in nucleation process of solid phase transformation thus nucleation speed also varies with time, seeing Table 2.2. It can be seen from this table that nucleation speed and embryo growth speed (accretion in all) varies along with passing through of time. And growth speed and accretion speed slowed gradually along with grown - up of the new phase of Sm2Co17. This reason is that solute atoms needed for continually growth of new phase of Sm2Co17 (or called continual growing coarse) need to be diffused from farther area (long range diffusion) so that will need longer diffusion time (Feng, Shi, Liu, 2002). It was observed also that the SmCo5 alloy formed embryo of new phase of Sm2Co17 as the beginning because of heat activated concentration undulating and fluctuate, then

| Table 2.2 Nucleation rate of new phase changes with time | ||||

|---|---|---|---|---|

| No. of Sm2Co17 new phase points (precipitate points) per unit volume of matrix phase (Fig. 2.7) | Volume increase from (e) | From (e) to (g) crystal coalescing getting | From (g) to (h) 550 - 600°C | From (h) to (i) volume increase inhomogeneous area appeared in new phase |

| Nucleation velocity: Used time \(t\) | 336" | 54" | 336" | 524" |

component atoms coming from SmCo5 matrix phase continual diffused to surface of the new phase of Sm2Co17 to make small precipitate points (embryo) grow up. Not all of small phase points (or embryos) can grow up (or coarse) independently to massive phase point of Sm2Co17 and survived because the SmCo5 alloy is metastable at below 850°C. And that part of small phase points (or embryos) was too small to be redissolved into SmCo5 matrix phase and disappeared because the smaller phase points have a bigger solubility so that they can not grow to be nucleus of new phase. In above mentioned process that the SmCo5 matrix phase is in metastable status transferred consequentially to a stable new phase of Sm2Co17 and as the result to lowered the unit free energy of system, and the new boundary is formed because the difference in structures between newly formed new phase of Sm2Co17 (in above mentioned process grown up nucleus of the Sm2Co17) and the matrix phase, that caused increase in free energy. The above mentioned process is formulated as:

\(\Delta G=\frac{3\sqrt{3}}{2}a^{2}hn\Delta H(\Delta T/T_{0}) - 3\sqrt{3}a^{2}+6ahn\sigma\) (2.5)

where \(\Delta G\) is variation of free energy; \(n\) is number of new phase point (embryo); \(\Delta H\) is the value for phase transformation of enthalpy; \(\Delta T\) is degree of super - cooling; \(T_{0}\) is equilibrium point of phase transformation; \(\sigma\) is energy on the boundary face between new phase and the matrix phase; \(a\) is height of the hexagonal prism.

It can be seen from Eq. 2.5 that increase in \(a\), \(h\), \(n\) and \(\sigma\) will increase the free energy for phase transformation also increase, and there is a functional relation between them; the easiness extend of phase transformation will determine the power required for nucleation. The power required for nucleation can be induced as follows: derives at first the extreme value in variation of the free energy using Eq. 2.5, the extreme value in variation of the free energy is:

\(\Delta G_{z}=\frac{3}{2}\sqrt{3}a_{z}^{2}h_{z}\sigma\) (2.6)

where \(a_{z}\) and \(h_{z}\) is the critical size of small phase points of Sm2Co17 at different temperature.

Power for nucleation is the energy vallation necessary to get across for the critical nucleus (Feng, Shi, Liu, 2002), and is the critical value for variation of the free energy (\(\Delta G_{z}\)). The higher the power of nucleation is the more difficult the phase transformation will be, i.e., the less the small phase points of Sm2Co17 precipitated from SmCo5 matrix phase will grow up. Only the small phase points of Sm2Co17 is bigger than the critical size of phase point those small phase points may grow up. In contrary, the smaller phase points will be automatically melted into the other phase of SmCo5.

D. Analysis on inhomogeneous nucleation

We have changed the view to find the area with many dislocations and layer dislocations in the matrix phase through observation by transmission microscope. These small areas with many dislocations and layer dislocations have comparatively more impurities so that the phenomenon of new phase points of Sm2Co17 precipitated from SmCo5 matrix phase occurs in advance and more phase points (embryo) are produced. Those indicate that the nucleation will be easy. This is due to that energy at interface between different phases of new phase points (embryos) of Sm2Co17 and impurities is low (compared with non - impurity phase) and the nucleation is inhomogeneous and needs a smaller driving force for phase transformation. This explained that in dynamic observation under heating environment the small phase point of teens A size moves quickly, and the phenomenon of two new phase point of Sm2Co17 gathered together along with prolonging of time was observed, seeing Fig. 2.7(e), (f) and (g) for two new phase spots of \(R\) and \(Q\) of Sm2Co17.

E. “Dynamic cross” and eutectoid decomposition

The precipitation of new phase of Sm2Co17 from the matrix phase of SmCo5 is long distance diffusion because Sm2Co17 and SmCo5 are constituted of different chemical compositions. Surely, condition for the diffusion is the step that atoms of matrix phase traverses the phase boundary under heat activation; the matrix phase has 3 crystal cells of SmCo5, and the samarium atoms in one of cells was instituted by a transit cobalt atoms to form the new phase of Sm2Co17. This type of short distance diffusion that atoms transit the boundary from the matrix phase to new phase of Sm2Co17 and long distance diffusion mentioned above processed continually; and for growth rate of new phase the long distance diffusion acts the decisive function. The above process is the dynamic cross diffusion of Sm and Co under heat activation that can be formulated as \(3SmCo_{5}\to 3SmCo_{5}-Sm + 2Co\to SmCo_{5}RE\), in detail the diffusion formula is \(3SmCo_{5}+Co + Sm\to 2SmCo_{5}+3RECo_{5}-RE + 2Co\to RE_{2}Co_{17}\), and \(3SmCo_{5}-Sm + 2Co\to Sm_{2}Co_{17}\). The metastable status at below 805°C is actually the temperature from 650°C to 750°C, at which the matrix phase processes the following eutectoid decomposition, i.e., \(SmCo_{5}\to Sm_{2}Co_{7}+Sm_{2}Co_{17}\).

F. Observation and analysis on defects in Sm2Co17 phase precipitated from matrix phase of SmCo5

In dynamic observation on SmCo5 in heating condition it was seen clearly that defects existed in the new phase of Sm2Co17 precipitated from matrix phase of SmCo5, seeing Fig. 2.7. The new phase precipitated from (g) to (i) had some defects which possess very low magnetic anisotropy. And amount of the defects in the phase of Sm2Co17 reached maximum at 750°C. We believe that this is the reason why the coercivity degrades by annealing at 750°C.

Fig. 2.9 Electron micrographs and electron diffraction patterns of the precipitation process

(a) The precipitation of Sm2Co7; (b) The SmCo5 matrix decomposes eutectoidally into Sm2Co7 and Sm2Co17 striations; (c) The Sm2Co7 striations change to Sm2Co17 particles

(For annealing conditions, see Fig. 2.7)

In the mutual effected energy between atoms and dislocation force field existed in dissolution precipitation of Sm2Co7 and Sm2Co17 from SmCo5. Is what kind of dislocation prone to form nucleation center for Sm2Co7 phase or Sm2Co17 phase? The Sm2Co7 phase is a hexagonal structure at high temperature and a rhombic structure at low temperature. No diffusion phase transformation from hexagonal structure to rhombic structure occurs in annealing. Generally, some screw dislocation avails to formation of nucleation center of Sm2Co7 phase, but many type of dislocations all avail to formation of nucleation center of Sm2Co17 phase (Zhou, et al, 1983).

SmCo5 phase and Sm2Co17 phase are coherent. Thus aberrance of crystal lattice and strain energy occurred in phase transformation at high temperature. For eutectoid decomposition of phases of Co and RE and Sm2Co7 from SmCo5 matrix phase there is the formula as below:

3RECo5 - Co + RE → 2 RE2Co17 3SmCo5 - Co + Sm → 2 Sm2Co17 3RECo5 - RE + 2Co → RE2Co17 3SmCo5 - Sm + 2Co → Sm2Co17

It was observed when temperature was raised to 650 °C that the new phase of Sm2Co17 appeared as integral hexagon and Sm2Co7 was in striation. The new phase appeared clearer but the striation microstructure appeared to be better grown. When temperature was raised to 750 °C the serried spots of Sm2Co17 new

phase transfer from area of Sm2Co7 phase, seeing Fig. 2.9 (c). Distribution of the precipitated spots of Sm2Co17 phase was littery, but between original precipitated big spots of Sm2Co17 phase there was a large serried row newly precipitated spots of SmCo5 phase.

H. Driving force and resistance for phase transformation of SmCo5

SmCo5 belongs alloy phase transformation of solid state, is a phase transformation of nucleation – growth of nucleus. Its phase transformation driving force is the difference of free enthalpy between new and old phases (Liu, Ren, Song, 2003):

\(\Delta G_{\text{driving force for phase transformation}} = G_{2}-G_{1}<0\) (2.7)

where \(G_{1}\) represents old phase, i.e., free enthalpy of SmCo5; \(G_{2}\) represents new phase, i.e., free enthalpy of Sm2Co17; \(\Delta G\) represents driving force for phase transformation.

\(\Delta G_{\text{driving force for phase transformation}} = G_{\text{free enthalpy of SmCo}_{5}}-G_{\text{free enthalpy of Sm}_{2}\text{Co}_{17}}<0\)

Necessary proceeding precondition for phase transformation is that the free enthalpy of Sm2Co17 new phase must be larger than that of the SmCo5 old phase. Phase transformation occurs spontaneously. Supposing \(n\) is atoms number, thus that each atom transforms from SmCo5 matrix phase to Sm2Co17 new phase will cause variation in free enthalpy as formulated below:

\(\Delta G=(G_{2} - G_{1})/n\) (2.8)

According to Eq. 2.5 and Eq. 2.6 as long as the inter - phase energy is worked out the \(\Delta G\) can be calculated, inter - phase energy between SmCo5 matrix phase and Sm2Co17 new phase consist of structural inter - phase energy and chemical inter - phase energy. The structural inter - phase energy is formed due to cutting off or weakening of atoms bond linkage, which caused heightened potential energy (Liu, Ren, Song, 2003). SmCo5 and Sm2Co17 are coherent. When Sm2Co7 and Sm2Co17 precipitate in SmCo5 crystals the atoms on the inter - phase will have a certain extent of mismatch because of their different lattice constants. When precipitate phase of Sm2Co7 exists in SmCo5 the degree of mismatch will be 0.8% in direction of \(a\) axis, and 2.3% in direction of \(c\) axis of the lattice; when precipitate phase of Sm2Co17 exists in SmCo5 the degree of mismatch will be - 3.2% in direction of \(a\) axis of lattice and 2.7% – 7.4% in direction of \(c\) axis of the lattice. While the degree of mismatch increased to a certain extent the property of the inter - phase will be changed and the fully coherent inter - phase will be broken that dislocation appears in the inter - phase to form partly coherent. Its nucleation power is smaller than that for non - coherence and larger for fully coherence. The total energy of interphase is less than \(0.5\ J/m^{2}\). The geometrical item is lowered from high to very low and chemical item enhanced from low to comparative high (Fidler, et al, 1980; Liu, Ren, Song, 2003; Zhou, et al, 1995). Configuration dislocation on interphase may reduce energy of interphase; inhomogeneous nucleation center for Sm2Co7 is dislocation; and inhomogeneous nucleation center for Sm2Co17 is crystal boundary. The structure of crystal lattice of SmCo5 is more complicated than that of normal 3d metals and some complicated dislocations, such as rhombic mast dislocation, dipole rhombic mast type dislocation, etc., may appeared in SmCo5 permanent magnetic alloy. The thickness of domain wall of SmCo5 is around 2.6 nm and the thickness of domain wall for cobalt is 14.7 nm, but the average action force of dislocation on domain wall in SmCo5 is large than that in cobalt. All of SmCo5, Sm2Co7 and Sm2Co17 belong to rare earth intermetallic compound, that the surface energy will be enhanced by chemical factors (chemical interphase energy is plus) in phase transformation or results in decrease in surface energy (chemical surface energy is minus). The difference between atoms bond linkage of interphase and interior atoms linkage of two phases causes enhancement in interphase energy. The bigger the concentration difference between SmCo5 phase and Sm2Co17 phase is the bigger the rising of interphase energy is caused to be. The nucleation of Sm2Co17 new phase may cause elastic aberrance and form stress field and elastic aberrance energy in lattice range around the nucleus. The desolution precipitation of SmCo5 matrix phase is more avail Sm2Co17 phase referring to elastic abearance energy. The Sm2Co7 phase of striation type, which was appeared at 650 - 750°C and observed by using 1000 kV HVEM, is actually the sheet phase precipitated along (0001) plane of matrix phase and perpendicular to c axis (Fidler, et al, 1980).

In conclusion, the above in situ and dynamic observation of SmCo5 is carried out by using transmission electronic microscope and in heating environment that provides driving force for phase transformation in thermodynamics. In the viewpoint of equilibrium state thermodynamics, the change in outside condition makes above mentioned system reach phase transformation point and causes phase transformation to form new phase. The processing of this process is the result that the difference of enthalpy between new phases (Sm2Co17, etc.) and old phase (SmCo5) is less than zero but their absolute value is bigger than the resistance.

Discussion: Key Findings on Phase Transformation and Magnetic Properties of SmCo₅ Magnets

SmCo5 permanent magnetic alloy possesses the maximum single axis anisotropy but the SmCo5 is unstable by below 805°C and then eutectoid decomposition occurs promptly. It is testified by experiment that SmCo5 is eutectoid decomposed to be Sm2Co7 and Sm2Co17 phases by annealing at temperature ranges 300 - 750°C. Also the magnetic crystal anisotropy of Sm2Co7 and Sm2Co17 is lower that that of SmCo5, thus scholars considered that nucleation coercivity of SmCo5 appeared by annealing at 750°C came down to Sm2Co7 and Sm2Co17 phases produced by eutectoid decomposition. The experiment discovered that eutectoid decomposition of SmCo5 by annealing at 300 - 600°C may cause precipitation of Sm2Co17 phase, but the coercivity of the alloy was not degraded remarkably and the coercivity of some specimen even was enhanced. Therefore, we took investigation emphases on eutectoid decomposition of Sm2Co7 phase itself for why SmCo5 appeared the minimum coercivity by annealing at 750°C, and carried out theoretical calculation on precipitated Sm2Co17 phase and the in situ and dynamic observation on high temperature phase transformation with transmission microscope. We preceded the in situ and dynamic observation using 1000 kV HVEM and videotaped the observation process. It was found through repeatedly studies that there were multi - defect areas in eutectoid decomposed Sm2Co17 phase at the temperature range of 650 - 750°C and the amount of multi - defect areas reached the maximum at 750°C. The magnetic anisotropy was the lowest in those multi - defect areas of Sm2Co17 phase through microscopy. That is why the coercivity degraded to the lowest by annealing at 750°C. The observed Sm2Co17 eutectoid decomposed from SmCo5 appeared as hexagonal (actually three dimension hexagonal prism) and can be calculated by making use of the nucleation field \(H_{n}\) theory. Thus theoretic minimum of nucleation field may be calculated by formulae as below:

\(2M_{s}H_{n}\frac{3\sqrt{3}}{2}a^{2}h=(3\sqrt{3}a^{2}+6ah)\nu\) (2.9)

The volume of regular hexagonal prism:

\(V = \frac{3}{2}\sqrt{3}a^{2}h\approx2.5981a^{2}h\)

The surface area:

\(S = 3\sqrt{3}a^{2}+6ah\approx5.1962a^{2}+6ah\)

Substitute into Eq. 2.9 it is derived:

\(2.5981a^{2}h\times2M_{s}H_{n}=(5.1962a^{2}+6ah)\nu\)

The result is:

\(H_{n}\approx(1/h + 1/a)\nu/M_{s}\) (2.10)

where \(\nu\) is energy density of domain wall; \(M_{s}\) is saturated magnetization intensity; \(h\) is the height of regular hexagonal prism; \(a\) is length of one side.

The \(\nu/M_{s}\) of SmCo5 is treble of that of Sm2Co17 through calculation, thus SmCo5 is easily nucleated at given \(a\), \(h\). Supposing radius of antimagnetic nucleus is \(R\) it is calculated that \(H_{n}=2,388\) kA/m while \(R = 10\) and \(H_{n}=238.8\) kA/m when \(R = 100\) (Buschow, et al, 1980). The above calculation approximated the length of diagonal of the regular hexagonal prism \(d=\sqrt{4h^{2}+4a^{2}}\) to be the radius of a sphere so that the sphere radius will be \(R = d/2=\frac{\sqrt{h^{2}+4a^{2}}}{2}\). It was

observed by electronic microscope that a considerable part of Sm2Co17 phase eutectoid decomposed from SmCo5 is also in sphere type so that the above supposition is acceptable. It can be seen from the calculation that sphere radius of anti - magnetic nucleation increases by ten times the nucleation field \(H_{n}\) will decrease to one of tenth. Defects in Sm2Co17 precipitated from SmCo5 took the most in amount when annealing at 750°C and expanded continually. Thus \(R\) is bigger and \(H_{n}\) is smaller. This indicated that the coercivity was degraded to the minimum by annealing at 750°C because of the production and growth of anti - magnetic nucleation centers in crystal granules. The nucleation centers were comparatively very big, the defects increased and grown, and the interior magnetic anisotropy is very small so that based on micro magnetics the calculated coercivity of nucleation center in an integral Sm2Co17 precipitate phase should be one level over the actual measured coercivity. We may induce very reasonably that the Sm2Co17 phase itself is not the center of nucleation. It can be seen from the calculation that the precipitate is more close to the Sm2Co17 structure chance is big for being minus magnetic anisotropy. Again to consider the magnetic anisotropy of Sm2Co17 is one quantitative level lower than that of SmCo5 and in precipitated Sm2Co17 phase the cobalt sublattice possesses weak magnetizable direction in magnetic anisotropy of \(c\) plane. Therefore, the areas of considerable volume existent with very low magnetic anisotropy may exist in some defect - filled Sm2Co17 phase, and these areas may become the centers of nucleation. The behavior of \(_{i}H_{c}\) in Fig. 2.4 and Fig. 2.5 can be explained as that the size of nucleation centers, with following the precipitated Sm2Co17 phase, grown dramatically in annealing stage and afterwards became slowness.

Referring to above mentioned it is summarized as follows:

- It was discovered in the in situ and dynamic observation on SmCo5 specimen in heating condition through 1000kV HVEM that the Sm2Co17 phase itself, precipitated from matrix phase of SmCo5, is not the anti - magnetic nucleation center. The multi - defect areas appeared in the Sm2Co17 phase at temperature from 620 - 750°C and reached the maximum amount at 750°C. These multi - defect areas in the precipitated Sm2Co17 phase possessed very low magnetic anisotropy and acted as anti - magnetic nucleation centers under effect of anti - magnetic field so that resulted in degradation of coercivity.

- SmCo5 permanent magnetic alloy was annealed at temperature from 200°C to 1000°C and then was quenched to room temperature. The coercivity of the alloy did not degrade visibly and the coercivity in some specimens was even enhanced slightly in measurement of the coercivity. It was found in dynamic observation that a mass of Sm2Co17 phase precipitated at all temperature from 300°C to 600°C, and in meantime a small quantity of Sm2Co7 appeared. This indicated that the eutectoid decomposition of SmCo5→Sm2Co7+Sm2Co17 occurred but the coercivity did not varied remarkably. Thus it can be concluded that when annealing the alloy at temperature ranges from room temperature to 1000°C the coercivity degraded drastically at 710 - 750°C and reached the minimum value at 750°C. That phenomenon did not attribute to eutectoid decomposed Sm2Co17 phase of low magnetic - crystal anisotropy.

3. The antielectron oblivion longevity \(\tau\) of SmCo5, measured by antielectron oblivion technique, was a flat curve and basically unaltered. There was small precipitate in a few minutes before, which indicated not to be vacant defects but the other type of defect, i.e., substituent type defect. The observed defect with transmission electronic microscope at 650 - 750°C was substituent type defect. The Sm3+ was substituted by Co due to incomplete precipitated Sm2Co17:

3SmCo5 - Sm + Co → Sm2Co17

The \(\tau\) and widened parameter \(S\) of Doppler curve did not vary with annealing time, that there was not visibly vacant defect.

4. Experiments testified that the coercivity is not sensitive to enriched cobalt. The coercivity is not influenced by surface but is influenced by pinning interior crystal boundary. The coercivity did not varied basically on long time annealing time.

5. Magnetic anisotropy of various Sm3+ neighboring near the distribution center of Sm3+ varies along with changing of temperature. The Sm3+ is more close to the Sm2Co7 structure it would be more possibility to be a minus magnetic anisotropy.

6. It was observed at 650 - 750°C that the location of striation Sm2Co7 phase transformed to very fine granular Sm2Co17 phase.

7. It was found in the in situ and dynamic observation on phase transformation of SmCo5 alloy at high temperature that nucleation speed increased with rising of temperature at temperature of 650 - 750°C and the nucleation speed varied along with passing of time.

8. It was found in the in situ and dynamic observation on phase transformation of SmCo5 alloy at high temperature that part of the new phase spots of Sm2Co17 precipitated from matrix phase of SmCo5 grown up and coarsened at high temperature ranges 650 - 750°C but the other part of them redissolved into the matrix phase of SmCo5.

9. It was found in the dynamic observation on phase transformation of SmCo5 alloy at high temperature that the eutectoid decomposition of Sm2Co7 and Sm2Co17 from SmCo5 was a slow process and the above precipitated two phase may exist in the same time but the precipitation of Sm2Co17 is easier and its existence time is longer in comparison with that those of Sm2Co7.

10. Phase transformation of SmCo5 is reversible at high temperature and that was testified by the in situ and dynamic observation experiments.

11. The following regularities are concluded through coercivity variation data of 11 specimens of SmCo5 measured at 475 - 1000°C, as listed Table 2.11: degradation of the specimen with a higher coercivity will be smaller than the degradation of the specimen with lower coercivity at 750°C after annealing. The specimen with higher coercivity will have less irreversible loss. The nucleation speed is related to the coercivity of specimen. The difference in performance of the alloy is related to difference in composition and manufacturing process. The difference in performance of specimen also influenced on variation of unit free energy of system and power for nucleation in phase transformation at high temperature.