Engineers need to know that permanent magnets are crucial for creating high-torque, high-efficiency electric motors. The choice of magnet—typically between Neodymium, Samarium Cobalt, and Ferrite—directly impacts the motor’s performance characteristics, including its power density, thermal stability, and overall cost. Understanding key magnetic properties like Remanence (Br), Coercivity (Hc), and the Maximum Energy Product ((BH)max) is essential for selecting the optimal material to meet specific application requirements, from industrial automation to electric vehicles.

Permanent Magnets in Electric Motors: What Engineers Need to Know

The silent hum of an electric vehicle, the precise motion of a CNC machine, and the powerful spin of a wind turbine all share a common, critical component: the permanent magnet electric motor. These motors have become the workhorses of modern industry, prized for their exceptional performance. For the design engineer, understanding the role of permanent magnets isn’t just academic—it’s fundamental to creating smaller, more powerful, and more efficient machines. This guide delves into what engineers need to know about permanent magnets in electric motors, focusing on torque, efficiency, and crucial selection criteria.

The Heart of the Motor: How Permanent Magnets Work 🧲

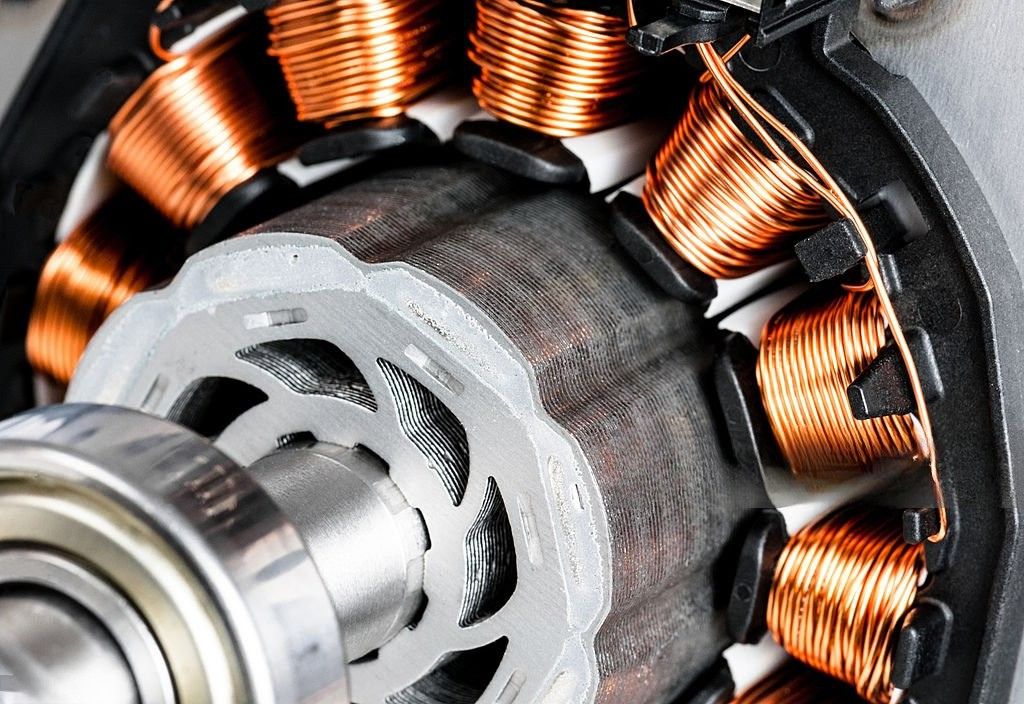

At its core, an electric motor converts electrical energy into mechanical energy through the interaction of magnetic fields. In a traditional induction motor, both the stationary part (stator) and the rotating part (rotor) are electromagnets, requiring a constant supply of electrical current to generate their magnetic fields.

A Permanent Magnet (PM) motor changes this dynamic. Instead of using electricity to create the rotor’s magnetic field, it utilizes permanent magnets. These magnets provide a constant, or “permanent,” magnetic flux. The stator windings are then energized, creating a rotating magnetic field that interacts with the rotor’s fixed magnetic field. This interaction between the two fields generates the torque that turns the shaft. The fundamental principle is Lorentz Force—the force exerted on a current-carrying conductor in a magnetic field. By precisely controlling the current in the stator windings, we can control the motor’s speed and torque with incredible accuracy.

Torque and Performance: The PM Advantage

One of the most significant advantages of using permanent magnets is the dramatic increase in torque density. Torque density is the amount of torque a motor can produce relative to its volume or weight.

Since the magnetic field from the rotor is generated by high-strength magnets rather than current-carrying windings, the rotor can be more compact and powerful. This has several key engineering benefits:

Higher Power Density: For a given power output, a PM motor can be significantly smaller and lighter than an induction motor. This is a game-changer for applications where space and weight are critical, such as in electric vehicles, aerospace, and robotics.

Faster Acceleration: A lower rotor inertia, combined with high torque capabilities, allows PM motors to accelerate and decelerate much more rapidly. This is essential for high-performance servo applications that require quick, precise movements.

Sustained Torque at Low Speeds: PM motors can deliver their maximum torque even at zero speed and maintain it through a wide speed range, providing excellent control and responsiveness.

The strength of the magnet, defined by its Maximum Energy Product ((BH)max), is directly proportional to the torque the motor can produce. A higher (BH)max value means a stronger magnet, resulting in greater torque for a given motor size.

Driving Efficiency to New Heights

Efficiency in an electric motor is the ratio of mechanical power output to electrical power input. Any energy that doesn’t contribute to mechanical work is lost, primarily as heat. PM motors are inherently more efficient than their induction counterparts, and the reason lies in the rotor.

In an AC induction motor, the rotor’s magnetic field is created by inducing currents into its windings or rotor bars. This current flow inevitably leads to resistive losses, known as I²R losses (where I is current and R is resistance). These losses generate significant heat, reducing the motor’s overall efficiency, especially under partial loads.

Because a PM motor’s rotor uses magnets, it has virtually zero rotor I²R losses. This single factor provides a major boost in efficiency. The benefits include:

Lower Energy Consumption: Higher efficiency directly translates to less wasted electricity, reducing operational costs over the motor’s lifetime.

Cooler Operation: With no current flowing in the rotor, PM motors run cooler. This reduces the need for complex cooling systems and can extend the life of the motor’s bearings and insulation.

Wider Peak Efficiency Range: PM motors maintain high efficiency across a broader range of speeds and loads compared to induction motors, which are typically optimized for a narrow band around their rated operating point.

Choosing the Right Magnet: A Guide for Engineers

The selection of the magnetic material is one of the most critical design decisions an engineer will make. It’s a balancing act between performance, operating environment, and cost. The choice hinges on understanding a few key magnetic properties and the characteristics of available materials.

Key Magnetic Properties

Remanence (Br): This is the residual magnetic flux density remaining in a material after the external magnetizing field is removed. A higher Br indicates a stronger magnet and leads to higher torque. It’s measured in Tesla (T) or Gauss (G).

Coercivity (Hc): This measures the material’s resistance to being demagnetized by an external magnetic field. A high coercivity is crucial for motors, as the stator field constantly opposes the rotor’s field. It’s especially important for withstanding high temperatures and fault conditions. It’s measured in Amperes per meter (A/m) or Oersteds (Oe).

Maximum Energy Product ((BH)max): This is the single most important figure of merit for a permanent magnet’s strength. It represents the maximum energy that can be stored in the magnet and is calculated from the demagnetization curve. A higher (BH)max allows for a smaller volume of magnetic material to be used for a given magnetic flux requirement, enabling more compact motor designs. It’s measured in MegaGauss-Oersteds (MGOe) or kilojoules per cubic meter (kJ/m³).

Common Types of Permanent Magnets

| Magnet Type | Max Energy Product ((BH)max) | Max Operating Temp. | Corrosion Resistance | Relative Cost | Key Applications |

| Neodymium (NdFeB) | 35-52 MGOe | ~80-230 °C | Poor | High | High-performance servos, EVs, drones |

| Samarium Cobalt (SmCo) | 18-32 MGOe | ~250-350 °C | Excellent | Very High | Aerospace, military, medical |

| Ferrite (Ceramic) | 3.5-5 MGOe | ~250-300 °C | Excellent | Very Low | Automotive blowers, small appliances |

| Alnico | 5-9 MGOe | ~450-550 °C | Good | High | Sensors, high-temp motors, generators |

Neodymium Iron Boron (NdFeB): These are the strongest commercially available magnets, offering the highest (BH)max. This makes them the go-to choice for high-performance applications where maximum torque and minimum size are paramount. However, they have a relatively low maximum operating temperature and poor corrosion resistance, often requiring protective coatings.

Samarium Cobalt (SmCo): SmCo magnets were the first rare-earth magnets developed. While not as strong as NdFeB, their key advantage is superior thermal stability and excellent corrosion resistance. This makes them ideal for applications involving high temperatures or harsh environments, such as military and aerospace systems.

Ferrite (Hard Ferrite/Ceramic): Composed of strontium carbonate and iron oxide, ferrites are the most widely used permanent magnets due to their extremely low cost. Their magnetic strength is significantly lower than rare-earth magnets, but their excellent corrosion resistance and good temperature stability make them suitable for countless cost-sensitive applications.

Alnico: Made from aluminum, nickel, and cobalt, Alnico magnets offer the best temperature stability of all, capable of operating at up to 550°C. They have moderate strength but relatively low coercivity, making them susceptible to demagnetization from strong external fields.

Design and Manufacturing Considerations

Engineers must also consider the practical challenges of integrating permanent magnets into a motor design.

Demagnetization: Magnets can lose their strength permanently if exposed to temperatures above their maximum rating or subjected to a sufficiently strong opposing magnetic field. Careful thermal analysis and fault condition modeling (e.g., short circuits) are essential to prevent this.

Mechanical Properties: Most high-strength magnetic materials, particularly NdFeB and Ferrites, are hard and brittle. They are susceptible to chipping or cracking and require careful handling during manufacturing and assembly. They are often manufactured via sintering and then machined to their final shape with diamond-grinding tools.

Cost and Supply Chain: Rare-earth elements like neodymium are subject to price volatility and geopolitical supply chain risks. For large-scale production, this can be a significant factor, pushing some designers toward ferrite-based or magnet-free motor designs like switched reluctance motors.

By carefully weighing these factors—performance requirements against temperature, cost, and manufacturability—engineers can select the ideal permanent magnet to build robust, efficient, and powerful electric motors for the next generation of technology.