Manufacturing Details

- Home

- Manufacturing Details

Permanent Magnet Manufacturing Process & Technical Details

Our production process integrates advanced technology, strict quality controls, and expert craftsmanship to deliver consistent and reliable magnetic products. Below is an overview of the complete manufacturing process and the technical details involved:

1. Raw Material Selection

We source premium-grade rare earth elements such as Neodymium, Samarium, Iron, and Boron to ensure superior magnetic performance. The purity and composition of these raw materials directly impact the final magnet properties, so we maintain strict quality checks from the start.

2. Powder Preparation

The raw materials are melted and rapidly cooled to form fine alloy ribbons. These ribbons are then pulverized into microscopic magnetic powders using jet milling or hydrogen decrepitation, depending on the magnet type. This process ensures particle uniformity and optimal magnetic alignment.

3. Compacting / Pressing

The magnetic powder is pressed into shapes using axial or isostatic pressing. During pressing, a magnetic field is applied to align the powder’s crystalline structure, which significantly enhances the magnet’s ultimate magnetic properties. We manufacture both anisotropic and isotropic magnets depending on the application.

4. Sintering Process

Pressed parts are sintered in a high-temperature vacuum or inert gas furnace. Sintering densifies the magnets and enhances their structural integrity. Our controlled sintering environments ensure minimal porosity and optimal grain boundary formation, which leads to improved magnetic strength and durability.

5. Machining and Surface Treatment

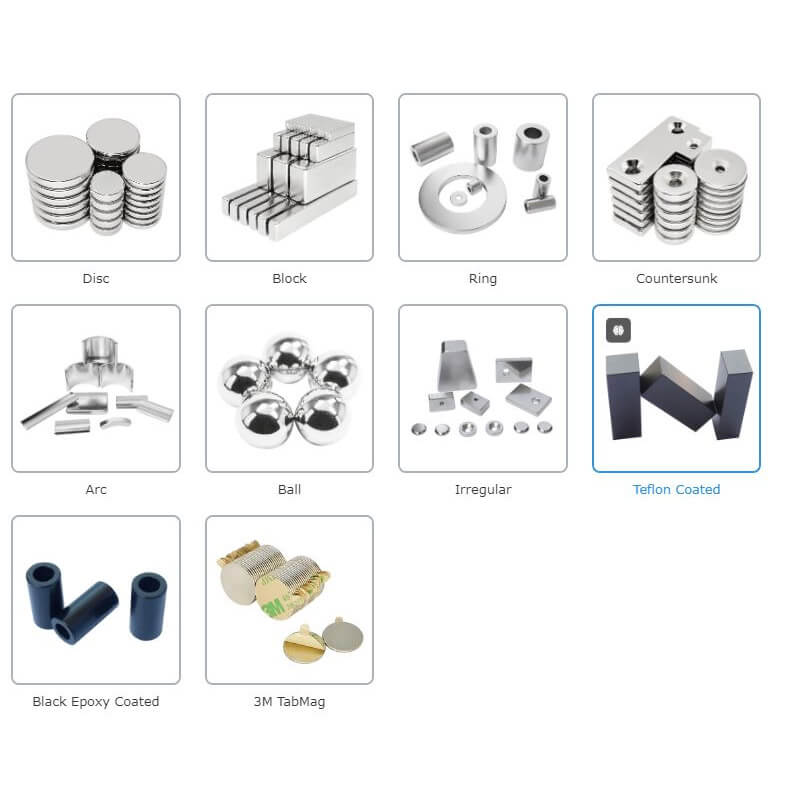

Once sintered, magnets undergo CNC machining, grinding, or wire-cutting to achieve precise dimensions and tight tolerances. Magnets are then cleaned and coated to protect against corrosion and mechanical wear. We offer various coatings, including:

- Nickel (Ni-Cu-Ni)

- Epoxy

- Zinc

- Gold

- Phosphate

6. Magnetization

The final parts are magnetized using powerful pulse magnetizers. The magnetizing direction and strength are configured based on customer application, whether it’s axial, radial, or multi-pole orientation.

7. Quality Control and Testing

Every batch of magnets goes through comprehensive testing:

- Magnetic performance testing (Br, Hc, BHmax)

- Dimensional inspection

- Surface treatment adhesion

- Salt spray & corrosion resistance tests

We comply with ISO 9001 and RoHS standards, ensuring our magnets meet both mechanical and environmental requirements.

8. Packaging and Shipping

Magnets are demagnetized (if needed for safety), labeled, and securely packaged using shielding materials to ensure safe transportation. We also provide customized packaging solutions to meet international logistics standards.